IRM Systems, an independent authority on emergency pipeline repairs, announced that as a result of a new and innovative approach to pipeline repair, it contributed to achieving dramatic cost-savings on the recent repair of a live subsea pipeline in the Java Sea, Indonesia. The objective of the operation was to seal a tear on a weld seam by installing a permanent repair solution.

IRM Systems began providing engineering services for the project in January 2015. Normally, the operation would have been executed by a major EPIC company – and nearly was – but in this instance, the operator decided to do something different. It decided that it should be executed by a smaller service contractor, drawing upon the services of a constellation of specialist providers, including IRM Systems.

A graphic image of a habitat installed over a pipeline.

A graphic image of a habitat installed over a pipeline.

New approach reduces costs without lowering margins

The “constellation” approach involved using vessels of opportunity, independent diving and survey contractors, engineering specialist IRM Systems, the equipment manufacturer, and the regulator. Despite the organizational challenges, this method allowed the operator to interface with one lean, flexible primary contractor. Because margins were not compounded by the multiple layers of contracting that traditionally make up the structure used by an EPIC company, the operator immediately realized the financial benefit. As for those companies executing the project, rates were not squeezed and risk was more equitably distributed.

Innovative method offers cost-effective alternative

"This project is solid evidence of great innovation, in which out-of-the-box thinking really produced dramatic cost-savings,” said Wander van Weerden, Project Manager for IRM Systems. “Much of what we are seeing in response to today’s low oil prices is contractors and their subcontractors taking more and more risk to offer a compounded savings to the client. The approach that was used to complete this complex repair project proves that it is a realistic, completely viable alternative."

To ensure that the project would succeed, the operator brought a certification body on board to assist with the engineering and advise on overall quality. Working with IRM Systems, the primary contractor selected the manufacturers and fabricators of the repair clamp, and conducted offshore surveys in cooperation with specialist survey contractors. The components of the repair solution were tested in Norway and the Netherlands in August, and successfully installed on to the live gas pipeline in October 2015, well within schedule.

Given the success of this project, the operator plans to use the approach used for this project as the standard template for more projects throughout the region. Not just repair projects, but for routine maintenance and inspection tasks.

Optimum results for less money

According to IRM Systems, the operator received the same high quality service and materials in the same amount of time, but for less money. “As for the service providers, it’s business as usual. It’s the way forward for the industry, whether oil prices are high or low,” said Rutger Schouten, General Manager of IRM Systems.

The key to the success of this project is twofold. “First, you must have a highly organized body to coordinate the project. It’s essential that it has a strong grip on all of the players,” said Rutger Schouten. “Secondly, the team must have hands-on experience that duplicates - or exceeds - that of bigger players. Without that, you will not achieve the same quality targets as those completed by bigger players.”

Light in the darkness

When it comes to effective project management, the industry has longed for value-added creativity. “This project illustrates that costs can be reduced while maintaining quality standards and operational excellence. When led by a reliable independent source, collaboration can be very powerful and extremely effective,” said David Obatolu, General Manager of IRMS UKWA. “For the industry, this approach offers a light as we navigate through – and beyond - the dark tunnel of low oil prices.”

Innovation holds key

Globally, low oil prices have boosted a jittery world economy. On the other hand, oil and gas exploration costs money. In order that the world economy and energy industry thrive, traditional practices must change. And change calls for innovation. For IRM Systems and its partners, innovation has resulted in a more cost-effective, professional approach to pipeline repair. Whether the industry rises to the occasion by challenging the status quo remains to be seen, but the future is clear for IRM Systems: innovation holds the key.

CGG

CGG The contracts awarded on behalf of the license partners include marine operations, marine construction, engineering, procurement and construction (EPC) of an unmanned wellhead platform as well as modifications at the Oseberg Field Centre.

The contracts awarded on behalf of the license partners include marine operations, marine construction, engineering, procurement and construction (EPC) of an unmanned wellhead platform as well as modifications at the Oseberg Field Centre. A graphic image of a habitat installed over a pipeline.

A graphic image of a habitat installed over a pipeline. The JIP will develop a set of guidelines to be incorporated into DNV GL

The JIP will develop a set of guidelines to be incorporated into DNV GL Almost 7,000 visits were made to Europe’s largest subsea event,

Almost 7,000 visits were made to Europe’s largest subsea event,  Block 14 is located in the Pelotas basin of the South Atlantic Ocean, approximately 200 kilometers off the coast of Uruguay. It covers an area of 6,690 square kilometers in water depths of 1,850 to 3,500 meters.

Block 14 is located in the Pelotas basin of the South Atlantic Ocean, approximately 200 kilometers off the coast of Uruguay. It covers an area of 6,690 square kilometers in water depths of 1,850 to 3,500 meters. The International Association of Oil & Gas Producers (IOGP)

The International Association of Oil & Gas Producers (IOGP) He graduated from the University of Glasgow with a B.SC. Hons in Civil Engineering and holds a Masters in Petroleum Engineering from Heriot-Watt University.

He graduated from the University of Glasgow with a B.SC. Hons in Civil Engineering and holds a Masters in Petroleum Engineering from Heriot-Watt University. Jez Averty, senior vice president for NCS exploration in Statoil. (Photo: Ivar Langvik)

Jez Averty, senior vice president for NCS exploration in Statoil. (Photo: Ivar Langvik) Aker Solutions

Aker Solutions GE Oil & Gas (NYSE: GE) has announced the creation of its new Oil & Gas Digital Solutions business, appointing Matthias Heilmann as head of the organization and Chief Digital Officer. GE also announced the development of a pilot program with BP and a business partnership with subsurface software company Paradigm.

GE Oil & Gas (NYSE: GE) has announced the creation of its new Oil & Gas Digital Solutions business, appointing Matthias Heilmann as head of the organization and Chief Digital Officer. GE also announced the development of a pilot program with BP and a business partnership with subsurface software company Paradigm. A new research report published by

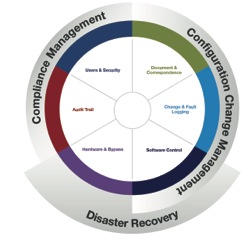

A new research report published by  Asset Guardian Solutions Ltd (AGSL)

Asset Guardian Solutions Ltd (AGSL) Siemens UK & Ireland

Siemens UK & Ireland Lay Vessel 105 and North Ocean 102 are docked to support operations at McDermott’s spoolbase facility in Gulfport, Mississippi.

Lay Vessel 105 and North Ocean 102 are docked to support operations at McDermott’s spoolbase facility in Gulfport, Mississippi. Aker Solutions

Aker Solutions The American Petroleum Institute's Global Industry Services department (API Global) has established a new and comprehensive Auditor Certification Program, which is the first to be developed by industry experts.

The American Petroleum Institute's Global Industry Services department (API Global) has established a new and comprehensive Auditor Certification Program, which is the first to be developed by industry experts.