Canadian Differentials Remain Strong Post-Wildfires

Canadian Differentials Remain Strong Post-Wildfires

Canadian oil sands supplies partially recovered in June, with production volumes approaching normal in early July. Canadian, Bakken and Rockies differentials remained strong, supported by the reduced supplies. A small Cushing crude stock draw in June will be followed by another small draw in July.

Russia Offer Ukraine Competitive Gas Prices

Gazprom is offering Ukraine’s Naftogaz somewhat lower gas prices than European suppliers for the third quarter, the head of the Ukraine's national oil and gas company Naftogaz has said. "The price offered by Gazprom is somewhat lower as of today than the one offered by European suppliers, though the market is very volatile and the price on the European market has started to lower," Andriy Kobolyev told reporters. Gas supplies from Europe are sufficient to provide Ukraine with reserves for the winter season.

Heat Wave in Italy Underpins Cooling Needs, But Prices So Far Under Check

Warmer weather so far during July has added 2 GWs of demand in Italy, with the week starting also with extra cooling needs of roughly 4 GWs. Day-ahead prices have, however, been generally in line with expectations so far in July, with maximum hourly prices also under check, most likely as thermal demand is being undermined by a weaker economy, generally healthy hydro levels, and more favorable gas pricing.

Coal Pricing Holds Steady Despite Weaker Oil

Coal pricing was mixed last week, although the fact that the market was able to hold onto sizeable gains posted in the prior week despite weaker oil prices illustrates that the market has found a vein of structural strength. Interestingly, deferred pricing for API#2 (Northwest Europe) and API#4 (South Africa) strengthened relative to the prompt, while the opposite was true of FOB Newcastle (Australia). PIRA continues to assert that 2017 prices are undervalued, although we are doubtful that prices can maintain the recent run in pricing. While China's thermal coal imports have turned positive year-on-year, India's imports remain notably below prior-year levels and do not look poised to emerge any time soon, particularly during the monsoon season.

EPA’s Finalizes SO2 Reg — Hits Some Plants, Spares Others

The U.S. EPA finalized designations for the 2010 SO2 NAAQS, classifying 61 areas, compared to 66 areas from February’s proposal. The five areas where EPA has backed off for now (no final action is being taken) include four in Texas and one in Oklahoma — all of which had been targeted in February’s proposal (contrary to those states’ own recommendations). EPA’s final four non-attainment regions include areas with coal plants in Illinois, Maryland and Michigan. All but one of EPA’s finalized designations for Texas agree with state recommendations, bearish for longer-term gas demand and power prices in ERCOT, though Regional Haze regs still await the outcome of legal challenges.

Weather and WASDE

With pollination in full swing for many, weather forecasts offer something for both the bull and the bear. Expected hot temperatures this week will be somewhat offset by additional precipitation for almost everyone in the Eastern Belt. Those west of the Mississippi River are forecast to receive even more rain on top of last weeks’ very impressive totals.

U.S. Ethanol Price Falls the Week Ending July 1

Production was over 1 MMB/D for the third time in four weeks. Corn prices tumbled after bearish USDA reports, boosting manufacturing margins. 2016-D6 RIN prices soar.

Resource Nationalism Loosening Amidst Weak Oil Prices

PIRA’s analysis of resource control policies around the world suggests a marked trend towards more investor-friendly policies in the upstream oil sector. Most notably, Saudi Arabia, Russia, and Nigeria all announced plans to sell stakes in state-owned upstream operators, and improved contractual terms could soon materialize in major producers, including Iran, the UAE, and Venezuela. The moves are being partially offset by prohibitive tax increases in some countries, in an attempt to support government revenues. But if prices remain below the levels of the past decade, as PIRA forecasts, we would not be surprised to see more widespread implementation of policies favorable for foreign or private investment.

U.S. Job Growth and Chinese Forex Reserves Data Point to Resiliency

This week’s economic developments highlighted the global economy’s resiliency as well as its potential vulnerabilities. The U.S. jobs data for June were constructive: they showed healthy gains in payrolls, but did not point to overheating in the labor market. The latest data on Chinese foreign exchange reserves were also positive for the outlook. At the same time, the U.S. dollar continued to strengthen, a fallout from the Brexit decision two weeks ago. In addition, the European banking sector remained under pressure.

U.S. Crude Stock Draw Disappoints

Crude stocks drew just 320 MB/D this past week, about one third the level PIRA expected. We believe floating stocks in the Gulf of Mexico were reduced to support the high import level. With floating stocks now likely more normal, PIRA expects July imports to reflect FOB cargo loadings, which imply lower than June imports and larger stock declines. For next week, we have crude stocks falling 620 MB/D with imports at 7.85 MMB/D.

Weather, a Fair-Weather Friend to Gas Bulls

The prospects for heavy summer cooling loads should favor a market “buying the dips,” despite prices retracing last week’s gains. Indeed, a sea change in sentiment has been on display as of late, whereby expectations for expanding cooling degree days (CDDs) have positively colored speculative positioning and price. Certainly, the latest snapshot of open interest in NYMEX/ICE futures encapsulates the shifting environment, which has seen Henry Hub (HH) prices rally ~30% month-on-month. Most notably, the long-to-short ratio between non-commercial longs and shorts continues to push deeper into new high ground, rising to ~1.1, the highest level since 2014.

How Low Can They Go? Utility-Scale Solar and the New Power Order

In recent months, several utility-scale solar PV projects have been announced at ultra-low prices, raising questions about downside risk to natural gas and other power sources. As a result, PIRA recently raised its 2025 U.S. solar generation outlook 41% above the previous outlook from fall 2015. However, PIRA does not see substantial downward medium-term flexibility for U.S. utility-scale solar PPA prices below current subsidized levels, assuming a link to fundamental economics. Nevertheless, in regions with strong insolation and meaningful incentive mechanisms, solar will continue to pressure other power sources as it continues to grow from its small base.

California Carbon Strengthens, Awaiting Regulatory Release

California carbon prices were up in June vs. May, but remained below the auction floor. Declines in open interest suggest that market players are not switching to the secondary market for procurement, but rather refraining from taking new positions altogether. There is little incentive to purchase allowances at the August auction. Re-offering of unsold consigned allowances raises the auction quantity and will require a higher bidding volume to clear. PIRA does see pricing once again exceeding the auction reserve this year. Cap-and-trade regulatory amendments will be released July 12th, addressing post-2020 caps and allocations, linkages and also unsold allowances.

The Manufacture of Ethanol-Blended Gasoline Sets Another Record

Inventories build by 390 thousand barrels the week ending July 1. PADD V received approximately 2.9 million gallons of imported ethanol from Brazil, only the second week this year in which imports were reported.

July WASDE Filled with Uncertainty

The 2016/2017 corn and soybean acreage numbers have turned into “knowns” for the July WASDE, but higher-than-expected old crop corn and soybean supplies in the Quarterly Stocks report just a few days ago may have more than a few scratching their heads at the World Board. Add to the mix these extremely fragile markets, and Tuesday’s outcome is far from a certainty in PIRA’s opinion.

Stress Lessens Post-Brexit

Financial stress continues to lessen post-Brexit. On the week, the S&P 500 flirted with record highs, while volatility declined and emerging market debt prices rose sharply. The dollar retains a mixed upward bias. It has continued to strengthen against the British pound and some of the Eastern European currencies. However, it has weakened against a host of Asian currencies.

Japanese Crude Runs Continue to Rise; Gasoline Demand Strength Drawing Inventory

Crude runs rose on the week as maintenance continues winding down. Crude imports moved higher by 0.9 MMB/D and crude stocks built 1.5 MMBbls. Finished product stocks built 1.1 MMBbls, with increases in all the products other than gasoline. Gasoline demand was relatively strong and stocks drew, while gasoil posted a significant stock build on lower yield and exports. Refining margins have remained soft with little barrel support other than fuel oil and naphtha.

Access to N.W. Europe Remains Critical Strategy for LNG Suppliers/Traders

Even with send-outs sputtering into the N.W. European market during the shoulder months of the late second and early third quarters, the need for access to the liquid pricing hubs at the Dutch Title Transfer facility (TTF) U.K. NBP has never been more pronounced. The Atlantic Basin market stands poised to absorb some 90-bcm/yr. of new supplies by 2020 (not including Yamal), and sellers are extremely active in securing a portion of this total.

A Look at PIRA's U.S. Shale Model Assumptions

The horizontal oil rig count reached a trough in mid-May. Despite this, shale production is not expected to immediately return to growth. PIRA expects the rig count to continue increasing at a gradual pace for the balance of the year and beyond. An estimated 400 horizontal oil rigs are currently needed to maintain production, which is 128 rigs higher than the current count of 272. Production is expected to shift to growth by 2Q17. On an annual basis, PIRA expects shale crude and condensate production to decline 330 MB/D in 2016 and 60 MB/D in 2017. This represents a 70 MB/D upward revision in 2017 versus our June Reference Case.

National Grid Paints a Bleak Picture for Demand – Maybe a Bit Too Aggressively

After gas demand in the U.K. finally grew last year for the first time since 2010, many hailed it as a case when demand finally bottomed out. Gas burn is now getting strong support in the U.K. in the form of a £18.08/ton carbon floor and coal-fired power stations are getting shut down. Future growth prospects hang on power sector growth, but the upside appears to be limited, particularly from the perspective of National Grid.

U.S. NGL Prices Decline

Mont Belvieu propane prices narrowly beat out broader energy markets by declining 5.7% on the week to settle near 50¢/gal (August). Butane futures fell in line with WTI (-7.3%) while ethane prices dropped nearly two cents to 21¢, the lowest level since May.

Strong U.S. Equity Performance Offsets Weakness of International Indices

The overall global equity market was unchanged for the week, with U.S. market gains offsetting weakness elsewhere. Gains in the U.S. market were broad based across most of the tracking sectors, except energy. Housing, retail, and consumer discretionary were the strongest performers. Internationally, the performance was mixed and tended to be weaker. Asia and Europe both displayed aggregated declines on the week of 1.2-1.5%.

Rough Week for Oil Prices

Oil prices fell $3.70/Bbl this past week with time spreads getting crushed on both sides of the Atlantic. There was not a specific story to point to but just a host of negative news. PIRA's outlook for the week ahead is that the market will continue to be range bound and should therefore find support within a couple of dollars from here.

Model of Long-Term Oil Price Basis for Project Evaluation

In June 2006, PIRA put forward a simple model to approximate the method used by some major oil companies to evaluate long-term investment projects. We have updated the results and not surprisingly prices are a lot lower.

The information above is part of PIRA Energy Group's weekly Energy Market Recap - which alerts readers to PIRA’s current analysis of energy markets around the world as well as the key economic and political factors driving those markets.

Photo courtesy: Oceaneering

Photo courtesy: Oceaneering Demonstrating our best practice approach to delivering superior products that incorporate optimum, high quality materials, our new pneumatic fender goes above and beyond the minimum requirements of the ISO 17357-1:2014 standard which recommends the use of synthetic tire-cords but does not make it mandatory, added Hepworth.

Demonstrating our best practice approach to delivering superior products that incorporate optimum, high quality materials, our new pneumatic fender goes above and beyond the minimum requirements of the ISO 17357-1:2014 standard which recommends the use of synthetic tire-cords but does not make it mandatory, added Hepworth.

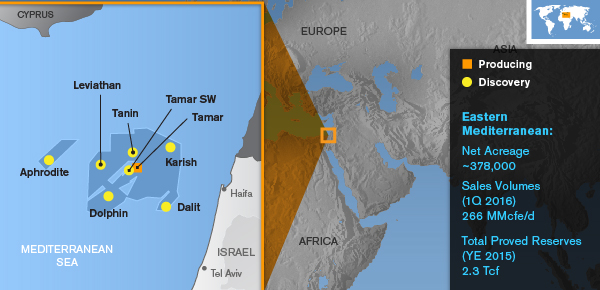

Photo courtesy: Qatar Petroleum

Photo courtesy: Qatar Petroleum

Canadian Differentials Remain Strong Post-Wildfires

Canadian Differentials Remain Strong Post-Wildfires GRAY, La. – Danos’ fabrication facility in Amelia now features on-site instrumentation and electrical services, including automation, safety and control systems.

GRAY, La. – Danos’ fabrication facility in Amelia now features on-site instrumentation and electrical services, including automation, safety and control systems.

Driven by its purpose of safeguarding life, property and the environment,

Driven by its purpose of safeguarding life, property and the environment, Reducing drilling and development spend has largely been the focus of services and equipment providers in the Gulf of Mexico – with the aim of lowering costs at the most capital intensive period of asset lifecycles. Often overlooked, Opex costs have grown in line with other upstream costs –

Reducing drilling and development spend has largely been the focus of services and equipment providers in the Gulf of Mexico – with the aim of lowering costs at the most capital intensive period of asset lifecycles. Often overlooked, Opex costs have grown in line with other upstream costs –  Subsea IMR provider,

Subsea IMR provider,

The global oil and gas industry has sent out a strong message about its commitment to maintaining the safety of its workforce in the downturn with international training standards body

The global oil and gas industry has sent out a strong message about its commitment to maintaining the safety of its workforce in the downturn with international training standards body

The Industry Technology Facilitator (ITF)

The Industry Technology Facilitator (ITF)