Apprentice Jens Erik Eriksen in Kværner and Norway’s minister of petroleum and energy Tord Lien marked the construction start on the Johan Sverdrup utility and living quarters platform on the island of Stord, north of Stavanger on Thursday, March 31, 2016.

“Johan Sverdrup is the biggest industrial project in modern times in Norway, and will create considerable value for society for generations to come. Today we are kicking off the construction of the utility and living quarters platform, which is the second of four platform currently under construction in the first project phase,” says Kjetel Digre, Statoil’s project director for Johan Sverdrup.

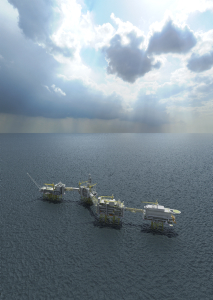

Johan Sverdrup platform. Credit: Statoil

Johan Sverdrup platform. Credit: Statoil

Statoil awarded a joint venture between Kværner and KBR the contract for engineering and construction of the topside for the utility and living quarters platform for the Johan Sverdrup field in June 2015.

Stord is central in a comprehensive Johan Sverdrup project. Kværner Stord will fabricate parts of the topside steel frame, and will also assemble all parts for the utility and living quarters platform before the platform is installed on the field in 2019. At peak around 2000 Kværner employees will be involved in Johan Sverdrup deliveries.

Kværner’s sub-supplier Apply Leirvik on Stord will construct the accommodation module for the living quarters platform, which will be the biggest on the Norwegian continental shelf (NCS).

The other modules for the utility and living quarters platform will be constructed at the Energomontaz Polnoc Gdynia (EPG), Mostostal Pomorze Gdansk (MPG), Mostostal Chojnice and Crist Offshore in Poland, as well as in Gothenburg, Sweden. Detailed engineering is performed at KBR’s office in Leatherhead, London, and at Apply Leirvik on Stord. The fabrication work was also kicked off today at two of the yards in Poland and at Apply Leirvik’s yard.

“The Johan Sverdrup project is growing every day. It is a complex puzzle with activities spread all over the world. We are 14,000 people working on the project every day in 2016, and together we will perform 100 million working hours. We depend on everyone delivering as required, and all pieces of the puzzle falling into place at the right time and with the right quality. Our top priority is a safe working environment. We do not want any injuries among personnel working for the Johan Sverdrup project,” says Digre.

The utility and living quarters platform will accommodate the crew working on the Johan Sverdrup field during the field life of 50 years. The platform will have the largest living quarters on the NCS with a capacity of 560 people. The platform will also accommodate the field’s control and emergency center, and some utility systems covering the whole field center.

The platform will be completed in the first quarter of 2019, before it is installed on the Johan Sverdrup field by use of the world’s largest heavy-lift vessel, the Pioneering Spirit.

Statoil’s Gullfaks A. Photo credit: Øyvind Hagen – Statoil

Statoil’s Gullfaks A. Photo credit: Øyvind Hagen – Statoil Hydrographic survey single beam echo sounder manufacturer

Hydrographic survey single beam echo sounder manufacturer  Songa Offshore

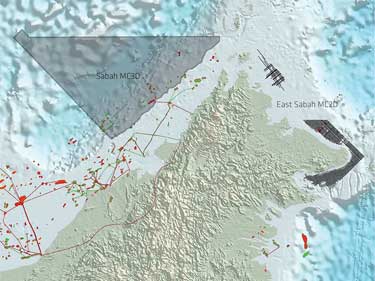

Songa Offshore Johan Sverdrup is by far the largest ongoing project on the Norwegian Continental Shelf for the next few years. Credit: Statoil ASA

Johan Sverdrup is by far the largest ongoing project on the Norwegian Continental Shelf for the next few years. Credit: Statoil ASA  As a result of a new initiative by

As a result of a new initiative by  Johan Sverdrup platform. Credit: Statoil

Johan Sverdrup platform. Credit: Statoil The Njord field. Credit: Statoil

The Njord field. Credit: Statoil Seagull Oil & Gas

Seagull Oil & Gas Aqueos Corporation

Aqueos Corporation Fraser Moonie, chief operating officer of Bibby Offshore

Fraser Moonie, chief operating officer of Bibby Offshore Photo credit: BSEE

Photo credit: BSEE Damen Anchor & Chain Factory (AKF)

Damen Anchor & Chain Factory (AKF) Archie Kennedy, Non-Executive Director, Bibby Offshore

Archie Kennedy, Non-Executive Director, Bibby Offshore Photo: Harald Pettersen / Statoil.

Photo: Harald Pettersen / Statoil. ASCO

ASCO The proprietary Delmar Quick Release (DQR) was successfully installed and activated on a traditionally moored semi-submersible MODU in the US Gulf of Mexico. Eight DQRs were installed in an offshore mooring systems and deployed for over 160 days in approximately 7800' of water.

The proprietary Delmar Quick Release (DQR) was successfully installed and activated on a traditionally moored semi-submersible MODU in the US Gulf of Mexico. Eight DQRs were installed in an offshore mooring systems and deployed for over 160 days in approximately 7800' of water.