Aberdeen-based standby vessel operator Atlantic Offshore Rescue has secured a five year charter with five, one year options to extend with Shell UK to support operations in the Gannet, Annasuria and the Dana Petroleum Triton Asset in the central North Sea.

Aberdeen-based standby vessel operator Atlantic Offshore Rescue has secured a five year charter with five, one year options to extend with Shell UK to support operations in the Gannet, Annasuria and the Dana Petroleum Triton Asset in the central North Sea.

John Bryce, managing director of Atlantic Offshore Rescue

Ocean Osprey, a brand new Class A tanker assist, rescue and standby ship will be used to provide emergency recovery, rescue cover, tanker assistance and general field support in offshore operations. The vessel is the first of a new H820 design from Havyard Ship Design and was developed in close collaboration with Atlantic Offshore.

The 66.9 metre long vessel was built in Passai, Spain by Zamakona shipbuilders over a fifteen month period to replace Ocean Searcher. Two further sister vessels are also under construction as part of the company's £300million fleet modernisation programme.

The new vessel has secured 30 jobs and is one of 12 Emergency Response and Rescue Vessels (ERRV) managed by the company from its Aberdeen base.

Ocean Osprey can accommodate up to 21 employees and has the capacity to rescue more than 300 persons. It will make its North Sea debut later this month to begin operations.

Atlantic Offshore Rescue is part of the Atlantic Offshore Group, which is based in Norway. Atlantic Offshore Rescue Ltd employs 350 people (approximately 330 seamen and 20 office-based staff) and provides multi-role offshore and emergency rescue and response vessels for many of the oil majors operating in the North Sea.

John Bryce, managing director of Atlantic Offshore Rescue, said: "Securing this charteris down to the first class vessels we offer clients, as well as the experience and professionalism of our team.

"Ocean Osprey features some of the most up to date shipping technology, replaces Ocean Searcher and secures 30 jobs. Launching the new vessel is also part of our ongoing commitment to provide the very best, cutting edge emergency response to those operating in the North Sea, an absolutely crucial part of all oil and gas operations."

In January this year, Atlantic Offshore Rescue commissioned a £6 million Class A ERRV vessel for a two year charter with Nexen Petroleum UK Ltd (Nexen) to provide emergency vessel cover for Nexen's flagship Golden Eagle Area Development in the North Sea.

Mr Bryce continued: "Obtaining this contract, our second long term charter this year, is a real milestone for Atlantic Offshore and, we look forward to fulfilling further contracts in the coming months."

Inclusive of Atlantic Offshore Rescue's 12 vessels, Atlantic Offshore Group currently operates a fleet of 24 ERRVs and PSVs and manages further PSVs on behalf of third parties.

The Group's aim is to continue to expand its capabilities within both the Norwegian and British sector of the North Sea and to be able to provide cross-border solutions reflecting the needs of its clients for both ERRVs and PSVs.

.

Caterpillar Marine

Caterpillar Marine UK-based

UK-based  Newbuild orders for Very Large Crude Carriers (VLCCs) are picking up in expectation of rising demand but risk putting the sector's recovery at risk, according to

Newbuild orders for Very Large Crude Carriers (VLCCs) are picking up in expectation of rising demand but risk putting the sector's recovery at risk, according to Tugs Fairmount Summit and Fairmount Alpine have towed rig ENSCO 5006 safely from Cyprus to Singapore. The Fairmount twins towed the rig over about 13,000 miles.

Tugs Fairmount Summit and Fairmount Alpine have towed rig ENSCO 5006 safely from Cyprus to Singapore. The Fairmount twins towed the rig over about 13,000 miles. Adding to its fleet of 37 conventional and ASD vessels,

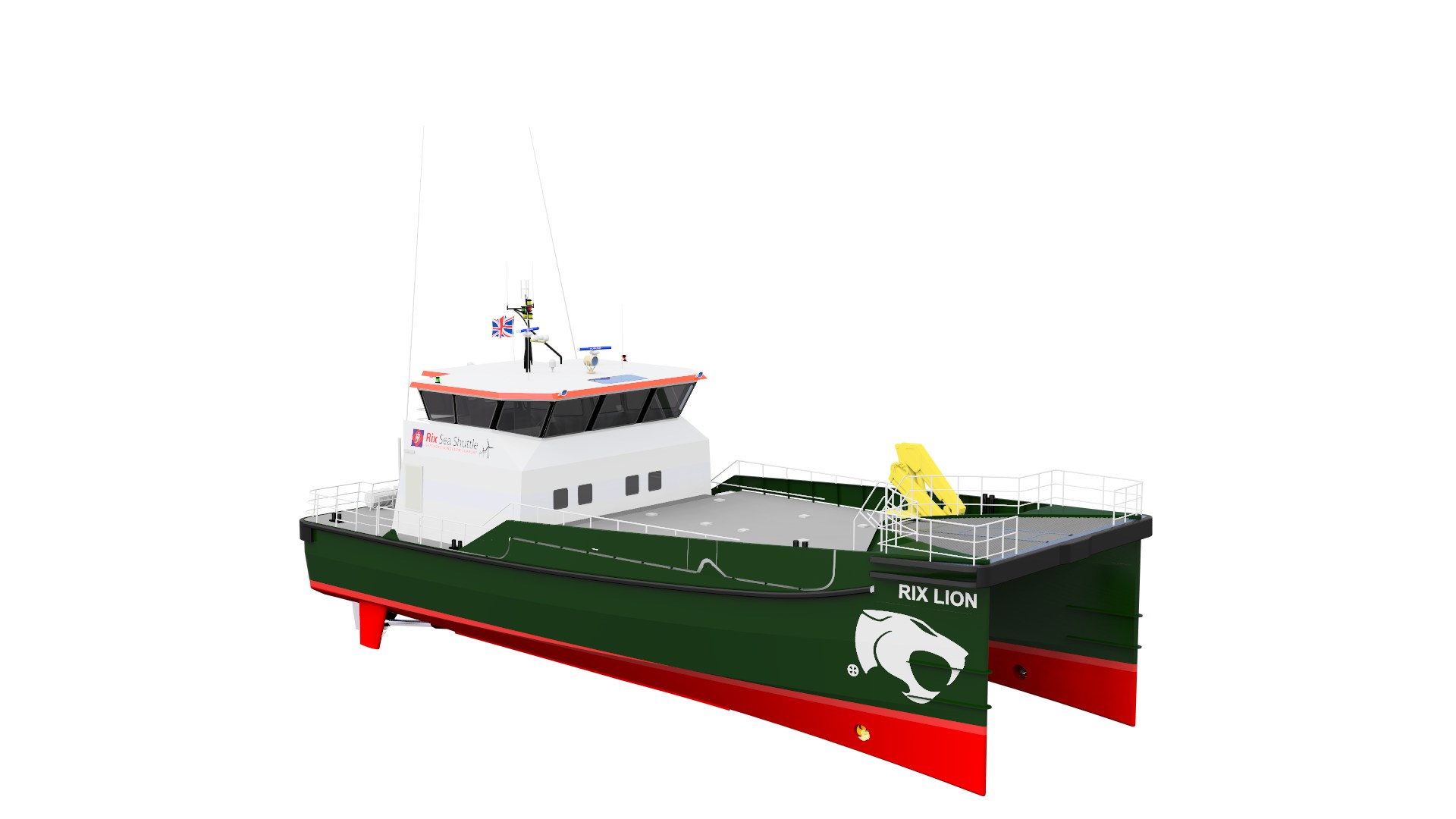

Adding to its fleet of 37 conventional and ASD vessels,  Aberdeen-based standby vessel operator

Aberdeen-based standby vessel operator  A starboard-side view of the Royal Thai Navy patrol boats.

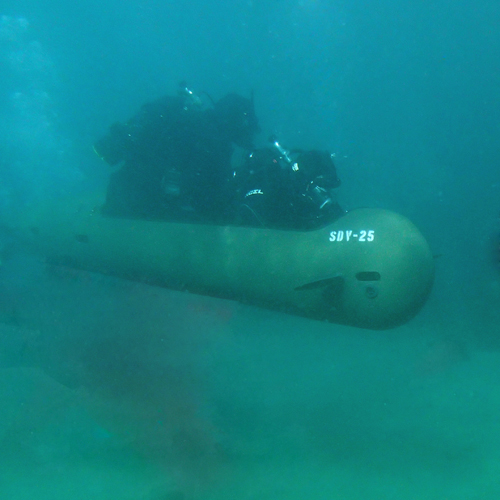

A starboard-side view of the Royal Thai Navy patrol boats. VideoRay LLC

VideoRay LLC The Damen shipbuilders

The Damen shipbuilders

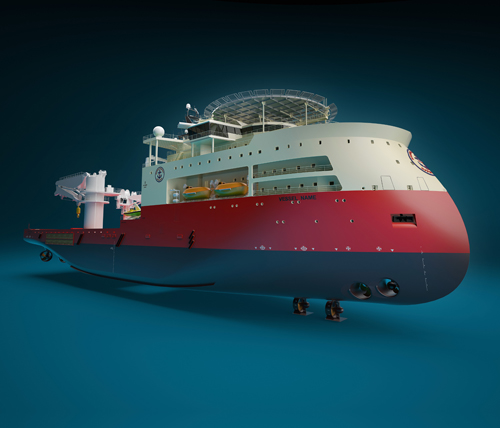

Ramform Titan

Ramform Titan James Fisher Defense,

James Fisher Defense, Ulstein SX165

Ulstein SX165 Rolls Royce UT 777

Rolls Royce UT 777 ABS Secures Prestigious FLNG Classification Contract

ABS Secures Prestigious FLNG Classification Contract Tug Fairmount Sherpa has towed rig Sevan Louisiana safely from Singapore to Curaçao. During the 11,500 miles voyage via Cape of Good Hope, stops were made in Port Louis (Mauritius), Walvis Bay (Namibia) and Port of Spain (Trinidad) to take bunkers and for crew changes.

Tug Fairmount Sherpa has towed rig Sevan Louisiana safely from Singapore to Curaçao. During the 11,500 miles voyage via Cape of Good Hope, stops were made in Port Louis (Mauritius), Walvis Bay (Namibia) and Port of Spain (Trinidad) to take bunkers and for crew changes.