To meet the rapidly growing demand for a wide variety of LNG related services, DNV GL has established a group of LNG experts in North America. In addition to deep LNG expertise, the Houston-based "LNG Solutions Group - Americas" is also experienced in all business, risk and regulatory matters specific to the North American market.

To meet the rapidly growing demand for a wide variety of LNG related services, DNV GL has established a group of LNG experts in North America. In addition to deep LNG expertise, the Houston-based "LNG Solutions Group - Americas" is also experienced in all business, risk and regulatory matters specific to the North American market.

With the increasingly strict regulation of sulphur emissions in force next year and the already tightened Emission Control Area regulation for the US, ship owners are likely to feel more pain by the rising fuel prices. For instance, due to the new regulations, Marine Gas Oil (MGO), will likely see a price jump in three months, possibly as high as 30% in the short term, and a minimum of 20% in the long term. This has impact well beyond the maritime industry.

"Judging from our list of recently completed projects, you can clearly see the market is about to reach a tipping point, from market, feasibility and risk studies to actual new-buildings, export and bunkering facilities," says Bjørn-Harald Bangstein, Director of Operations Maritime Advisory, Americas (photo).

"Judging from our list of recently completed projects, you can clearly see the market is about to reach a tipping point, from market, feasibility and risk studies to actual new-buildings, export and bunkering facilities," says Bjørn-Harald Bangstein, Director of Operations Maritime Advisory, Americas (photo).

As of July 2014 there are 116 LNG fuelled vessels in total (50 vessels in service and 66 on order). Of these, 75 are classed by DNV GL (46 in in service, 29 newbuildings), which gives DNV GL a market share of 65%. "We are now doing what we can to meet pent-up demand for LNG services also beyond the maritime industry by drawing on our expertise from Oil and Gas. This allows us to offer an unrivalled set of capabilities, from major export or liquefaction projects to small scale bunkering and everything in between," says Bjørn-Harald Bangstein.

"More than any other company, DNV GL has championed LNG as a solution for some of the main challenges facing the maritime industry: fuel cost and emission reductions. Combined with the abundance of cheaper natural gas in North America this contributes to a surge in LNG activities. We are happy to now see shipowners, yards, ports, bunkering operators and LNG proponents in general acting to be well positioned for LNG," says Bjørn-Harald Bangstein.

Regulatory certainty underway

"Through our interfaces with the US Coast Guard, both formal and informal, we know that they are now finalizing the remaining regulatory requirements on a detailed level. They are doing so in an open and consultative manner that involves the industry and prevents surprises and misunderstandings. Naturally there could be additional state, county and municipal regulations. But with a national regulatory framework designed to prevent major hazards using a risk based approach, particular local variations can be addressed through risk assessments, allowing for a consistent and predictable national regulatory framework," he says.

Drawing on experiences also from previous LNG projects around the world, the Houston-based group can offer class and advisory services throughout the value chain of LNG. The group has the following sets of competencies:

LNG as fuel, Class and Statutory Requirements

Regulatory advisory

Operations and Bunkering:

• DNV GL's Recommended Practice for bunkering

Crew training standard

Feasibility studies ship and shore facilities:

• Technical

• Financial

• Risk assessments

• Gas dispersion analyses

• Technology qualification

Verification

Waterway suitability assessments

Navigational risk assessments

A selection of DNV GL's recently completed LNG projects in North America show a trend towards a tipping point:

• For IMO, DNV GL carried out a Feasibility Study on the use of LNG as fuel in North America.

• Waterway Suitability Assessments for several planned North American LNG export terminals

• A comprehensive risk assessment study on LNG bunkering for MARAD, the US Government's Maritime Administration.

• Security and Risk assessment study for Washington State Ferries

• Market feasibility study for LNG America

• Classification of two LNG ready container ships for Matson

• Classification of two LNG fueled RoRo Container ships for Crowley

• Hosted visits from USCG and Transport Canada for familiarization with LNG as a fuel in Norway

• Technology qualification for flashing liquid expanders

• Quantitative risk assessment studies for North American export terminals

• Termpol 3.15 risk assessements for all planned LNG export terminals in Canada

• Industry-wide LNG Fuel Advisory Council headed by DNV GL's Tony Teo in 2011.

DNV GL has published several widely referenced industry documents such as Rules for Classification: Gas Fuelled Ship Installations (last update Jan 2014), Recommended Practice for Development and operation of liquefied natural gas bunkering facilities (Jan 2-014) and Competence Related to the On Board Use of LNG as Fuel (April 2003).

The "Rules for Classification: Gas Fuelled Ship Installation" was developed in 2000 and later introduced to the IMO which was adopted as the "IMO Interim Guidelines on Safety for Natural Gas-Fuelled Engine Installations in Ships", Resolution MSC.285(86) on June 1, 2009.

Barge Master

Barge Master  Gulf Marine Services

Gulf Marine Services  Danish product tanker carrier

Danish product tanker carrier  Vard Marine

Vard Marine To meet the rapidly growing demand for a wide variety of LNG related services, DNV GL has established a group of LNG experts in North America. In addition to deep LNG expertise, the Houston-based "LNG Solutions Group - Americas" is also experienced in all business, risk and regulatory matters specific to the North American market.

To meet the rapidly growing demand for a wide variety of LNG related services, DNV GL has established a group of LNG experts in North America. In addition to deep LNG expertise, the Houston-based "LNG Solutions Group - Americas" is also experienced in all business, risk and regulatory matters specific to the North American market. "Judging from our list of recently completed projects, you can clearly see the market is about to reach a tipping point, from market, feasibility and risk studies to actual new-buildings, export and bunkering facilities," says Bjørn-Harald Bangstein, Director of Operations Maritime Advisory, Americas (photo).

"Judging from our list of recently completed projects, you can clearly see the market is about to reach a tipping point, from market, feasibility and risk studies to actual new-buildings, export and bunkering facilities," says Bjørn-Harald Bangstein, Director of Operations Maritime Advisory, Americas (photo). Crowley Maritime Corporation's

Crowley Maritime Corporation's Damen Fast Crew Suppliers (FCS) 2610 at Wind Energy in Hamburg. The two new vessels, to be named SeaZip 3 and SeaZip 4, will be mobilized in transporting personnel and small quantities of freight to North Sea offshore wind farms.

Damen Fast Crew Suppliers (FCS) 2610 at Wind Energy in Hamburg. The two new vessels, to be named SeaZip 3 and SeaZip 4, will be mobilized in transporting personnel and small quantities of freight to North Sea offshore wind farms. Final touches have been made to the Damen Walk 2 Work vessel , a completely new and innovative design for the offshore support vessel market.

Final touches have been made to the Damen Walk 2 Work vessel , a completely new and innovative design for the offshore support vessel market. First delivery of Damen ASD Tug 2810, ARC Towage signed four contracts total in Barcelona, Spain

First delivery of Damen ASD Tug 2810, ARC Towage signed four contracts total in Barcelona, Spain Fugro Pioneer second of three vessels to be delivered to Fugro in 2014

Fugro Pioneer second of three vessels to be delivered to Fugro in 2014 Three tugs of

Three tugs of

"STA 4.0 is certainly a logical advance from the technical point of view in line with market expectations, but its availability also brings immediate benefits for our end-users," says Roger Ringstad, Managing Director, Seagull Maritime AS. (photo)

"STA 4.0 is certainly a logical advance from the technical point of view in line with market expectations, but its availability also brings immediate benefits for our end-users," says Roger Ringstad, Managing Director, Seagull Maritime AS. (photo) Modeled After Innovative Gulf of Mexico Terminal Hub, C-Port

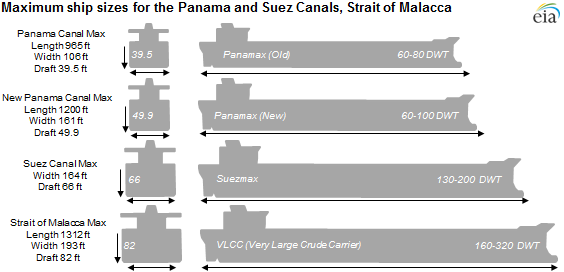

Modeled After Innovative Gulf of Mexico Terminal Hub, C-Port Ships carrying crude oil and petroleum products are limited by size restrictions imposed by several of the main thoroughfares of maritime navigation: the Panama Canal, the Suez Canal, and the Strait of Malacca. These size restrictions provide another way to classify the large tankers that carry most of global crude oil and petroleum product trade.

Ships carrying crude oil and petroleum products are limited by size restrictions imposed by several of the main thoroughfares of maritime navigation: the Panama Canal, the Suez Canal, and the Strait of Malacca. These size restrictions provide another way to classify the large tankers that carry most of global crude oil and petroleum product trade. ABS,

ABS,