Demands for increased collaboration in the oil and gas industry are being reflected through a record rise in vessel shares, according to Peterson, the international energy logistics provider.

The company, which is leading the way in collaborative vessel sharing, has seen a record number of vessel sharing arrangements since the turn of the year.

Seven shares were arranged between operators in the central and Northern North Sea throughout January and February. All were facilitated by Peterson through the Aberdeen Marine Logistics Alliance (AMLA), a vessel sharing initiative designed to maximise efficiency and reduce marine logistics costs.

Left to right: Kees Wouters, Marine Project Supervisor; Jekaterina Mjackova, Marine Business Analyst, Eric Witton, Marine Manager; Loek Sakkers, Director Projects

Left to right: Kees Wouters, Marine Project Supervisor; Jekaterina Mjackova, Marine Business Analyst, Eric Witton, Marine Manager; Loek Sakkers, Director Projects

As the facilitator of AMLA, Peterson helps members source cost effective solutions for their unscheduled shipping requirements by arranging vessel shares with other companies operating in the North Sea, thus reducing both financial costs and environmental impact.

During 2014 and 2015, despite increasingly challenging market conditions, the combined financial benefit for companies participating in ALMA shares was £2 million, together with a reduction in CO2 emissions of approximately 800 tonnes, the equivalent of removing 275 cars from the road for a year.

With 15 years of experience in combining sailings via an efficient pool of supply vessels and shared supply bases, Peterson has developed in-depth knowledge and expertise of vessel sharing which is supported by the continuous development of supporting software solutions.

Loek Sakkers, Director of projects, Peterson said: “As was recently highlighted by Oil & Gas UK and others, there is an urgent need for widespread collaboration in the North Sea. We share this view and believe significant opportunities exist within the supply chain to do just that through increased vessel sharing. We believe the recent unprecedented number of vessel shares indicates that the industry is not only listening to the calls for greater collaboration but responding positively.

“We have a long established record in providing vessel sharing initiatives, including the successful Southern North Sea pool, and are delighted to be transferring this expertise to the wider North Sea region.”

Commenting on the arrangement, James Crawford, managing director of Wood Group PSN in the UK and Africa, said: “Our commitment is to contributing to the industry’s long-term sustainability and we are focused on working in collaboration with partners across the sector to find new opportunities to work together.

“Working with AMLA/Peterson is a strong example of this, and we are confident of the mutual benefits created by this model of combined sailings, which we believe can become best practice for the industry in the long-term.”

As well as addressing operators’ reactive vessel requirements through AMLA, Peterson is working with a number of UKCS operators to establish a formal pool for scheduled cargo movements. The pool offers members significant efficiency gains together with maximum fleet flexibility. When an operator charters a vessel independently, it is usually hired on a per day basis regardless of requirements. In a pool, the operator can use a vessel one day and the next day the vessel can be used by another operator. When the fleet available comprises of multiple vessels, the flexibility and availability is increased. Peterson’s role is to focus on maximum fleet utilisation and optimising vessel use per individual operator to reduce overall idle time.

Vessel sharing is one of a range of services offered by Peterson’s Integrated Marine Services (PIMS). Based at new premises within Peterson’s existing quayside base at Waterloo Quay, Aberdeen, the team provides services including all types of marine and vessel audits, inspections and surveys, the provision of expert marine personnel, dynamic positioning and marine engineering.

BOURBON

BOURBON Leading United Arab Emirates shipyard

Leading United Arab Emirates shipyard  These range from three recently delivered work crane boats for Kuwait Oil Company - optimized for duties such as heavy lifting, oil-pollution control, SPM hose handling, and supply to remote areas – to two modified 42 meter long crew boats (FNSA-3 and FNSA-4) for Fujairah National Shipping Agency. The latter vessels are capable of speeds in excess of 30 knots and customized to execute operations such as security duties, fast transportation of offshore personal and cargo, and the rapid supply of fuel and freshwater.

These range from three recently delivered work crane boats for Kuwait Oil Company - optimized for duties such as heavy lifting, oil-pollution control, SPM hose handling, and supply to remote areas – to two modified 42 meter long crew boats (FNSA-3 and FNSA-4) for Fujairah National Shipping Agency. The latter vessels are capable of speeds in excess of 30 knots and customized to execute operations such as security duties, fast transportation of offshore personal and cargo, and the rapid supply of fuel and freshwater. Left to right: Kees Wouters, Marine Project Supervisor; Jekaterina Mjackova, Marine Business Analyst, Eric Witton, Marine Manager; Loek Sakkers, Director Projects

Left to right: Kees Wouters, Marine Project Supervisor; Jekaterina Mjackova, Marine Business Analyst, Eric Witton, Marine Manager; Loek Sakkers, Director Projects Gibdock has confirmed its role as one of the offshore industry’s pre-eminent shiprepair and conversion yards through its selection for the afloat mobilization of Seajacks Scylla, the largest and most advanced windfarm installation jack-up ever built.

Gibdock has confirmed its role as one of the offshore industry’s pre-eminent shiprepair and conversion yards through its selection for the afloat mobilization of Seajacks Scylla, the largest and most advanced windfarm installation jack-up ever built. LFC 3000 artist impression

LFC 3000 artist impression Capable of intervening in the most complex environments, she boasts a bollard pull of 307 t

Capable of intervening in the most complex environments, she boasts a bollard pull of 307 t

Falck Safety Services

Falck Safety Services Lance1. Photo credit: Wilhelmsen Ship Service

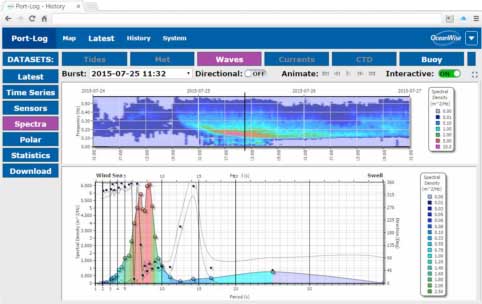

Lance1. Photo credit: Wilhelmsen Ship Service Output from Port-Log’s new waves processing capability.

Output from Port-Log’s new waves processing capability. Since 2008, the

Since 2008, the  Fugro has been awarded an inspection, repair and maintenance (IRM) contract by Petrobras in Brazil.

Fugro has been awarded an inspection, repair and maintenance (IRM) contract by Petrobras in Brazil. Crowley Maritime Corporation

Crowley Maritime Corporation Life today demands a 24/7 connection, but reception on the water is notoriously uneven. Dropped calls and marginal service are a thing of the past for users of

Life today demands a 24/7 connection, but reception on the water is notoriously uneven. Dropped calls and marginal service are a thing of the past for users of  The Brave Tern, a vessel used for the installation of wind turbines at sea, dominated the Rotterdam skyline on February 23rd. The 132 meter long ship was jacked up to a height of about seventy meters to test its extended legs.

The Brave Tern, a vessel used for the installation of wind turbines at sea, dominated the Rotterdam skyline on February 23rd. The 132 meter long ship was jacked up to a height of about seventy meters to test its extended legs. McDermott International, Inc.

McDermott International, Inc.