A major logistical challenge

Mammoet has broken several world records in moving a huge 20,300t FPSO into AF Offshore Decom’s decommissioning and recycling facility where it can be dismantled in a controlled, environmentally responsible manner.

A record-breaking 748 axle lines of SPMT and 30 power packs have been used – making this project a double world-first for both the largest number of axle lines and the heaviest weight carried by SPMT.

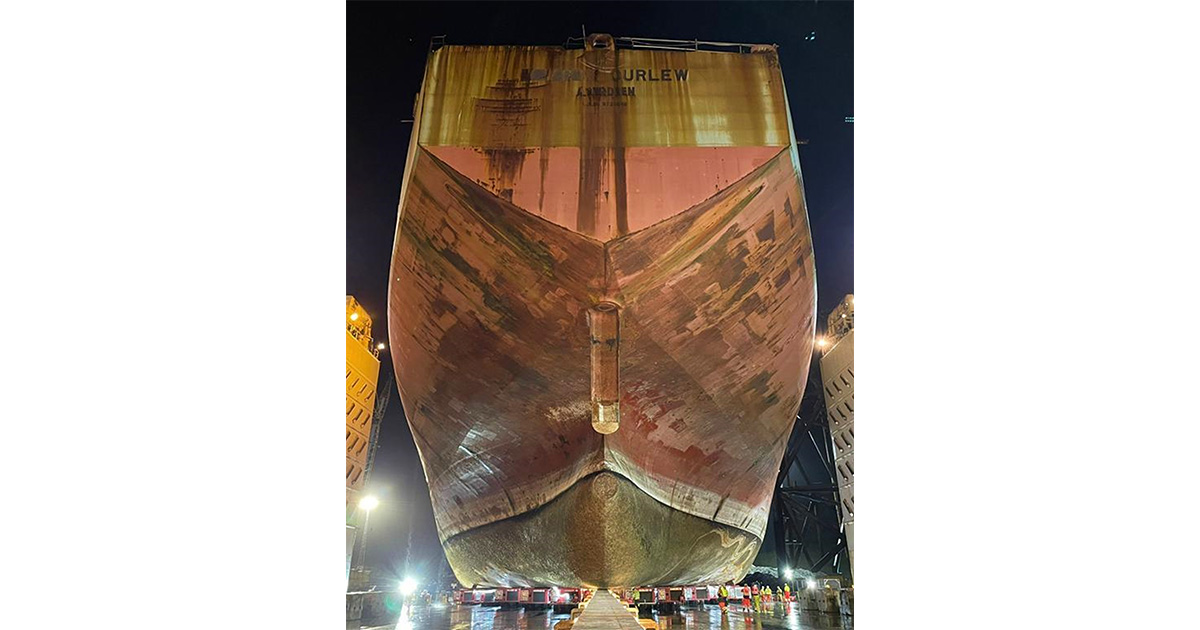

The Curlew FPSO had operated in the North Sea for over 20 years, helping to provide crucial gas supplies to Europe. When it reached the end of its operational life owner Shell sought the most environmentally responsible way to dismantle the vessel and reuse as much of its materials as possible. AF Offshore Decom is the main contractor for the Curlew FPSO decommissioning project and Mammoet was the chosen partner for the load-in and set-down operation.

This meant that Curlew was to be transported to AF Offshore Decom’s AF Environmental Base Vats in Norway where this could be carried out in a controlled manner, with over 95% of materials reused. But getting Curlew to the facility would require an unprecedented feat of logistics in moving the 235m long, 20,300t FPSO from its semi-submersible vessel and onto land, to enable the most efficient decommissioning process.

Curlew FPSO on SPMTs. Credit: AF Gruppen/Woldcam

Curlew FPSO on SPMTs. Credit: AF Gruppen/Woldcam

Dorien Frequin, Branch Manager Norway at Mammoet explains: “The load-in of Curlew to the decommissioning yard presented some major challenges – not only in terms of its size and scale but also because the nature of its structure meant that it would deflect when moved around, potentially jeopardizing the transport operation. It was recognized that specialist expertise would be needed and so we began our involvement with AF Offshore Decom and COSCO SHIPPING Heavy Transport early in the project to ensure we had the best possible approach in place.”

Record-breaking SPMT move

This process was started years before the execution of the project, with detailed planning required not only for the engineering scope but also the operational challenges too.

Ludo Mous, Director Operations at Mammoet Europe continues: “Safety was our first priority and we identified that having a single professional operating all SPMTs would be the best method to use. This meant that risks from miscommunication between operators were removed but required a high level of expertise to ensure all electronics worked together and maintained accuracy – especially as performance of the SPMTs would need to be adapted during the move. We also had to adapt the SPMT technology to work in this way – it is a world first, after all!”

“Alongside the operator there were thirteen other Mammoet professionals placed at specific points around the vessel to monitor progress and communicate with the operator when needed.”

Alongside putting in place comprehensive plans, it was critical that rigorous testing was carried out before executing the move. This was first completed onshore where the crew tested the full trailer arrangement, and then again on board with Curlew in situ. This meant that Mammoet came to site several days before the execution date in order to ensure this could be done without impacting the schedule.

Credit: AF Gruppen/Woldcam

Credit: AF Gruppen/Woldcam

Special pre-engineered fillings were put between the SPMTs and the FPSO which corrected the deflection of the hull so that the trailers were at the same level to optimize their required stroke. These fillings allowed Mammoet to make fine adjustments to keep the huge structure stable and in the correct shape as well to best accommodate the anticipated deflection of the hull.

Ludo Mous continues: “As a team and as individuals we have a lot of experience in delivering large scale load-ins, and this background was key to us developing the most effective plan for moving Curlew. But it is always critical to test methodologies in practice wherever possible, and it was particularly important here given such a procedure had never been attempted before.”

“We needed to test exactly where and how the SPMTs could best support the vessel, observe how this impacted movement in the hull, and make any necessary adjustments to ensure the move went smoothly.”

Credit: AF Gruppen/Woldcam

Credit: AF Gruppen/Woldcam

Safe, controlled decommissioning

The extensive planning, engineering work and testing paid off – with Curlew moved on schedule into position for AF Offshore Decom to begin the environmentally responsible dismantling process. As Dorien Frequin observes, the load-in scope has played a key role in achieving this:

“Moving an entire 20,300t FPSO from a semi-submersible vessel to a yard was an ambitious goal that had never been completed before - but one that was critical in allowing AF Offshore Decom to achieve the most sustainable decommissioning program possible.

“We were proud that Mammoet’s expertise was key to achieving this – both in terms of the engineering knowledge to find a safe methodology, and also the incredible operational skill of our professionals on site in executing it accurately.”