Strategically located Gibraltar shipyard Gibdock has continued its run of technically advanced offshore support vessel repair and maintenance projects, securing a contract involving a returning customer. The Viking Vanquish (photo), a high capacity 3D seismic survey vessel operated for CGG, has undergone a 21-day programme of works, leaving the shipyard’s drydocks in mid-September prior to sea trials.

Strategically located Gibraltar shipyard Gibdock has continued its run of technically advanced offshore support vessel repair and maintenance projects, securing a contract involving a returning customer. The Viking Vanquish (photo), a high capacity 3D seismic survey vessel operated for CGG, has undergone a 21-day programme of works, leaving the shipyard’s drydocks in mid-September prior to sea trials.

Based in France, CGG operates 23 seismic survey vessels, after acquiring Fugro’s geoscience division earlier this year - claimed to be the largest high-end seismic fleet in the industry.

John Taylor, Gibdock operations director, says: “We are really building up momentum in this demanding sector of the shiprepair business. Our ability to attract contracts from the top players in the industry reflects confidence in our workforce, and our safety procedures. We are now the yard of choice for demanding offshore vessel projects in the Mediterranean.”

The scope of work carried out on Viking Vanquish included a tailshaft withdrawal and the full overhaul of the shaft, couplings, liners and related equipment. This complex process required cutting away a section of the stern tube to gain access.

Are Skaanevik, technical superintendent for ship manager CGG Eidesvik, says: “The project went very well. We chose Gibdock largely because of the capacity and capabilities of its machine shop, which we called upon extensively. We have had a very good experience and I hope that this will be the start of a good long-term relationship.”

“This was certainly not a straightforward or standard job,” explains Mr Taylor. “Usually the couplings can be found in the engine room, without access complications. This was not the case on this project, but we nonetheless managed to finish on schedule.” Gibdock also machined liners for the tail shaft, which were not supplied pre-machined.

The 93.3m long, 8,621grt Viking Vanquish (built 1998) is owned by Norwegian company Eidesvik and was converted for seismic operations in 2007. Towing 12 x 8km streamers as standard, the vessel is capable of acquiring high quality data in all conditions.

Gibdock also carried out a series of load tests on the Viking Vanquish’s many winches and eye-plates, as well as a range of other machinery and pipe works. The yard renewed propeller blade seals and blasted and painted the vessel’s exterior.

Commenting on a period of sustained workload in the offshore sector at the yard, Gibdock managing director, Richard Beards, says: “This project adds another reference to our growing body of work in this specialised market for 2013, following a series of contracts for seismic survey, dive support, pipelayer and other offshore vessel types secured in the past year.”

Mr Skaanevik highlights another notable aspect of the project as using a cleaning product from Ultraclean AS, believed never to have been used before in shiprepair. The product, a combination of gel and chemicals, was applied to remove corrosion on Viking Vanquish’s gun-deck and cranes then washed away with water, to prepare surfaces for coating. CGG, Eidesvik and Gibdock expressed satisfaction with the results of using a product that may provide an environmentally-friendly alternative to conventional blasting.

.

In its capacity as Focal - MOOG Components Group representative in Scandinavia and Holland, the

In its capacity as Focal - MOOG Components Group representative in Scandinavia and Holland, the  Fairmount

Fairmount Strategically located Gibraltar shipyard

Strategically located Gibraltar shipyard Bechtel,

Bechtel,

ABB,

ABB, BOURBON

BOURBON Wagenborg. The vessel including the Barge Master system will be ready in the first quarter of 2015. NAM will use the motion compensated crane to service and maintain gas production platforms in the North Sea.

Wagenborg. The vessel including the Barge Master system will be ready in the first quarter of 2015. NAM will use the motion compensated crane to service and maintain gas production platforms in the North Sea.

Full Picture' technology delivery for new Korean and Chinese offshore units

Full Picture' technology delivery for new Korean and Chinese offshore units

close to the company’s office in Clearwater. The vessel was suffering from an oil leak, making a fast repair necessary. Using one of the company

close to the company’s office in Clearwater. The vessel was suffering from an oil leak, making a fast repair necessary. Using one of the company

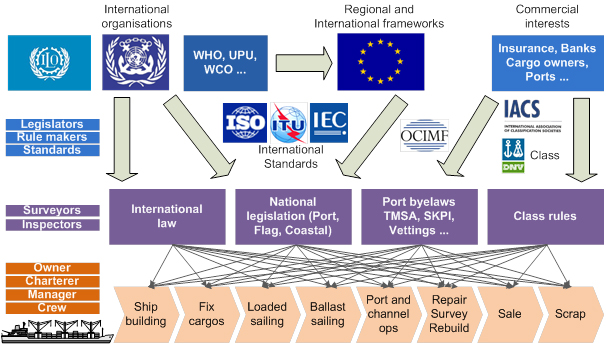

A new three year European Research Project, partly funded by the EU has been launched to help increase efficiencies in regulation compliance and enforcement for the maritime sector. e-Compliance will facilitate tighter integration and co-operation in the fragmented field of regulatory compliance. It will closely align with the EU e-Maritime initiative of which a key priority is supporting authorities and shipping operators to collaborate electronically in regulatory information management.

A new three year European Research Project, partly funded by the EU has been launched to help increase efficiencies in regulation compliance and enforcement for the maritime sector. e-Compliance will facilitate tighter integration and co-operation in the fragmented field of regulatory compliance. It will closely align with the EU e-Maritime initiative of which a key priority is supporting authorities and shipping operators to collaborate electronically in regulatory information management.

contracted by ADNATCO-NGSCO to deliver ship performance monitoring solutions that will help to optimize vessel performance and subsequently aim to reduce fuel consumption and carbon emissions. The entire project will be carried out by Unique System FZE, acting as agents for the Iceland based energy management company Marorka ehf. Commissioning and technical support will be provided by Unique Marorka Support Services which is a joint venture set up by Marorka ehf and Unique System FZE.

contracted by ADNATCO-NGSCO to deliver ship performance monitoring solutions that will help to optimize vessel performance and subsequently aim to reduce fuel consumption and carbon emissions. The entire project will be carried out by Unique System FZE, acting as agents for the Iceland based energy management company Marorka ehf. Commissioning and technical support will be provided by Unique Marorka Support Services which is a joint venture set up by Marorka ehf and Unique System FZE. The 154 foot patrol craft CHARLES DAVID JR is the seventh vessel in the Coast Guard's Sentinel-class FRC program. To build the FRC, Bollinger Shipyards used a proven, in-service parent craft design based on the Damen Stan Patrol Boat 4708. It has a flank speed of 28 knots, state of the art command, control, communications and computer technology, and a stern launch system for the vessels 26 foot cutter boat. The FRC has been described as an operational "game changer,” by senior Coast Guard officials.

The 154 foot patrol craft CHARLES DAVID JR is the seventh vessel in the Coast Guard's Sentinel-class FRC program. To build the FRC, Bollinger Shipyards used a proven, in-service parent craft design based on the Damen Stan Patrol Boat 4708. It has a flank speed of 28 knots, state of the art command, control, communications and computer technology, and a stern launch system for the vessels 26 foot cutter boat. The FRC has been described as an operational "game changer,” by senior Coast Guard officials.