Lerwick Port Authority have inaugurated a new Vessel Monitoring System (VMS) which utilizes the latest technology to improve the handling of ship movements at the busy Shetland port.

Transas, a world-leader in providing harmonized integrated solutions to the maritime industry, has installed the system across four sites covering the port area – port control in the main building and three remote stations, at Rova Head north of Lerwick and Maryfield and Kirkabister, on the island of Bressay, monitoring the northern approaches, inner harbor and southern approaches, respectively. Fibre and microwave links supply data back to port control.

Lerwick Harbour’s port control room and the newly installed Vessel Monitoring System, with Deputy Harbourmaster Alexander Simpson (left) and Port Controller Douglas Garrick (right). Credit: John Coutts.

Lerwick Harbour’s port control room and the newly installed Vessel Monitoring System, with Deputy Harbourmaster Alexander Simpson (left) and Port Controller Douglas Garrick (right). Credit: John Coutts.

The completion is being marked today (Friday 19 August, 2016), with invitations extended to port users to view the new system.

The modernizing VMS project, including the Transas contract, telecommunications and civil works, cost £450,000.

The Port Authority’s Deputy Harbourmaster, Captain Alexander Simpson, said: “The VMS is already a great asset for Port Control in handling shipping movements and providing navigational assistance. It combines data from multiple sensors in very user-friendly vector chart operator display units, extends Port Control’s VHF radio range, displays weather information and linked cameras deliver CCTV coverage – all enhancing the efficiency and safety of operations.

“The investment in the VMS is just one of several projects expanding the port’s infrastructure at a time when we are welcoming larger vessels – for example, the biggest cruise ship yet at Lerwick arrived this week.”

The new VMS is based on the high-end Navi-Harbour software solution from Transas. Hardware equipment scope consists of Class A AIS Transponders, Northrop Grumman Sperry Marine Vision Master radars, a Jotron VHF Communication System, Gill Meteorological sensors, general IT hardware platform and an APC Power Backup System.

“The Transas Ship Traffic Control solutions installed at Lerwick Harbour will provide tools for coordinated approach to maritime traffic control, monitoring and decision support which is vital in the era of rapid digital transformation,” comments Frank Coles, Transas CEO.

As part of a wider project to refurbish the Authority’s office in Albert Building, the port control room in Albert Building has been completely renovated, including a new server room. Transas closely collaborated with the Authority to design a new layout for the service within the building and contracted local support from H Williamson & Sons for installation and ongoing maintenance.

As part of its comprehensive customer support program, Transas also provided the Authority with an Operator Training Course and Maintenance Service Plan.

Conversion of the ground floor of Albert Building to a new reception and offices is underway, for completion by year-end as part of the phased refurbishment program.

About Lerwick Harbour

Lerwick is “Britain’s Top Port”, the most northerly commercial harbour in the country, handling more than 10,000 vessel movements in-and-out of the port annually, plus numerous movements within the harbour, and servicing a range of industries, along with the Shetland community. It is a leading centre for the fishing sector; for the offshore oil and gas industry in the Northern North Sea and North-Eastern Atlantic; Shetland’s lifeline ferry port to the Scottish mainland and a popular-port-of-call for cruise ships. Lerwick is a Trust Port, with the Authority responsible for management, maintenance and regulation, with all profits reinvested in the harbour.

About Transas

Transas’ vision is to lead the way in creating an ecosystem of harmonised integrated solutions in safety, navigation and ship operations. In creating these solutions Transas unites global maritime stakeholders in the future of e-Navigation and operations.

True to its vision, Transas has introduced THESIS, the Transas Harmonized Eco System of Integrated Solutions. THESIS is a flexible data resource where Ship, Fleet Operations, Academy (simulation & training) and Ship Traffic Control can all be connected to the ecosystem, effectively a community working together on a cloud based shared data platform to enable smarter operations, safety and navigation. United into a single environment, navigation, simulation, vessel traffic, and fleet management systems become a decision support tool using the data provided by Transas software solutions. Transas operates more than 20 own regional offices and has a global network of partners around the world.

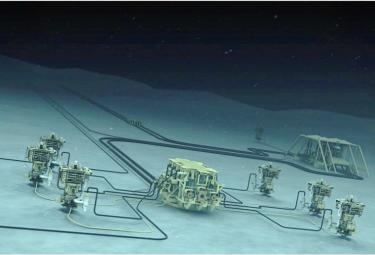

Skandi Açu: Photo credit: DOF Subsea

Skandi Açu: Photo credit: DOF Subsea Lerwick Harbour’s port control room and the newly installed Vessel Monitoring System, with Deputy Harbourmaster Alexander Simpson (left) and Port Controller Douglas Garrick (right). Credit: John Coutts.

Lerwick Harbour’s port control room and the newly installed Vessel Monitoring System, with Deputy Harbourmaster Alexander Simpson (left) and Port Controller Douglas Garrick (right). Credit: John Coutts. The U.S. Coast Guard has certified

The U.S. Coast Guard has certified  Specialist aluminium boatbuilder,

Specialist aluminium boatbuilder,

Allseas’ dynamically positioned single-lift installation/decommissioning and pipelay vessel “Pioneering Spirit” successfully executed her maiden heavy lift project, removal of the 13,500 t Yme mobile offshore production unit (MOPU) in the North Sea, 100 km off the coast of Norway, on 22 August 2016 for Repsol Norge AS.

Allseas’ dynamically positioned single-lift installation/decommissioning and pipelay vessel “Pioneering Spirit” successfully executed her maiden heavy lift project, removal of the 13,500 t Yme mobile offshore production unit (MOPU) in the North Sea, 100 km off the coast of Norway, on 22 August 2016 for Repsol Norge AS. Add Energy, the international oil and gas upstream consultancy provider, has expanded its operations with the launch of a new advisory service, ADDvisor.

Add Energy, the international oil and gas upstream consultancy provider, has expanded its operations with the launch of a new advisory service, ADDvisor. Dale Milward, Director of EPRS and subsea services, STATS Group

Dale Milward, Director of EPRS and subsea services, STATS Group Independent subsea remotely operated vehicle (ROV) service provider,

Independent subsea remotely operated vehicle (ROV) service provider,  Exxon Mobil Corporation

Exxon Mobil Corporation Sparrows Group and SPIE Oil & Gas Services have strengthened their existing service portfolios by signing a global agreement to work in collaboration to support the energy sector.

Sparrows Group and SPIE Oil & Gas Services have strengthened their existing service portfolios by signing a global agreement to work in collaboration to support the energy sector. Ashtead’s Deflection Monitoring System (DMS) during mobilization.

Ashtead’s Deflection Monitoring System (DMS) during mobilization. The international science community’s newest ocean research platform, a deep-rated remotely operated vehicle (ROV) called SuBastian, will be positioned and navigated using acoustic and inertial technologies supplied by Sonardyne Inc., based in Houston.

The international science community’s newest ocean research platform, a deep-rated remotely operated vehicle (ROV) called SuBastian, will be positioned and navigated using acoustic and inertial technologies supplied by Sonardyne Inc., based in Houston. Hydraulic fracturing has been a hugely controversial subject in many countries and has increasingly become the focus of legislation in the US. The state of Colorado has seen the most recent push for new restrictions – activists have obtained over 200,000 signatures to introduce two new initiatives on Colorado’s November 8th ballot. If passed, these initiatives would impose the toughest regulations on the hydraulic fracturing industry to date – increasing local control and dramatically limiting where fracking can take place. Initiative 75 would provide local governments with the authority to regulate oil and gas development in a manner that supersedes statewide regulations, whilst initiative 78 would prohibit fracking within 2,500 feet of houses, parks, schools, playgrounds, and clean water sources.

Hydraulic fracturing has been a hugely controversial subject in many countries and has increasingly become the focus of legislation in the US. The state of Colorado has seen the most recent push for new restrictions – activists have obtained over 200,000 signatures to introduce two new initiatives on Colorado’s November 8th ballot. If passed, these initiatives would impose the toughest regulations on the hydraulic fracturing industry to date – increasing local control and dramatically limiting where fracking can take place. Initiative 75 would provide local governments with the authority to regulate oil and gas development in a manner that supersedes statewide regulations, whilst initiative 78 would prohibit fracking within 2,500 feet of houses, parks, schools, playgrounds, and clean water sources. The partnership brings together the manufacturing and technological excellence of two leading companies in the oil and gas space, and also marks India’s entrance into local subsea equipment manufacturing.

The partnership brings together the manufacturing and technological excellence of two leading companies in the oil and gas space, and also marks India’s entrance into local subsea equipment manufacturing.