Harvey Gulf and Metizoft have signed a framework agreement on maintenance and quality assurance of the Inventory of Hazardous Materials (IHM). Vessels with IHM documentation must according to the requirements of IMO Guidelines - Ship Recycling; MEPC 197 (62) be maintained at all times and reflect the actual ship sailing. More and more shipping companies see the need to comply with the more stringent requirements, says Chief Marketing Officer Øyvind Sundgot.

Harvey Gulf and Metizoft have signed a framework agreement on maintenance and quality assurance of the Inventory of Hazardous Materials (IHM). Vessels with IHM documentation must according to the requirements of IMO Guidelines - Ship Recycling; MEPC 197 (62) be maintained at all times and reflect the actual ship sailing. More and more shipping companies see the need to comply with the more stringent requirements, says Chief Marketing Officer Øyvind Sundgot.

"This agreement is one of several benefits of Harvey Gulf's focus on Health, Safety and Environment, which also form the basis for system solutions to the company's vessels," says Corby Autin, Executive Vice President of QHSSE / HR. "The agreement initially includes 10 vessels in operation, and future new buildings will be subject to continuous maintenance and quality assurance of documentation at Metizoft.

"Through the agreement with Metizoft, IHM documentation is maintained according to the current regulations and Metizoft is helping to ensure that we comply with the requirements at all times."

More and more countries have ratified or are at least getting closer to ratifying the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, which addresses the requirements for IHM and makes ship owners responsible for compliance.

"We are very pleased to be a partner in Harvey Gulf's focus on the environment. The collaboration shows that Harvey Gulf is strategic in their choices in terms of meeting future requirements," says Sundgot.

Changes in the market earlier than expected

"A lot has happened in a short time, and this future requirement that will include all of the world's seagoing vessels above 500 tons deadweight at an earlier stage than some anticipated," Sundgot adds. "The European Union formally adopted the requirement on 30 December 2013, with some adjustments based on IMO - Hong Kong Convention. The new EU Ship Recycling Regulation means that EU-flagged vessels of 500 GT and over will be required to carry an Inventory of Hazardous Materials (IHM). When calling at EU ports, vessels from non-EU countries will also be required to carry an IHM identifying all hazardous materials on board. This means that the maintenance and quality assurance of the documentation is strengthened and it will therefore be very important for owners to have control of this."

Inventory of Hazardous Materials (IHM) requirements.

- EU-flagged newbuildings are required to have onboard a verified IHM with a Statement of Compliance at the earliest by 31 December 2015 and at the latest by 31 December 2018.

- Existing EU-flagged vessels are required to have onboard a verified IHM with a Statement of Compliance at the latest by 31 December 2020 (or if the ship is to be recycled, the IHM should be on board from the date when the European list of ship recycling facilities is published, expected to be by the end of 2016).

- Non-EU-flagged vessels calling at EU ports are also required to have onboard a verified IHM with a Statement of Compliance at the earliest by 31 December 2020.

A known difference is in the material declarations (MD) for the EU SRR, which will include two additional hazardous materials.

- PFOS (Perfluorooctane sulfonic acid) shall be prohibited. PFOS is chronically toxic, injurious to reproduction, carcinogenic, toxic to aquatic organisms and widely distributed in the global environment. In the marine industry, it can be found in fire-fighting foams of the type AFFF on vessels carrying inflammable fluids and those with helicopter decks, rubber and plastic materials (i.e., cable sheaths, PVC flooring, gaskets and seals) and coatings (i.e., paint).

- HBCDD (Brominated Flame Retardant) is to be listed in the IHM. HBCDD is very persistent, bioaccumulative and toxic to aquatic organisms; it causes long-term adverse effects on the aquatic environment. It is classified and labelled as dangerous for the environment. In the marine industry, this can be found in expanded polystyrene (EPS) used for cryogenic insulation, such as for liquefied gas tanks (LGT), refrigerated areas, thermal insulation boards (i.e., foam materials), rubber and plastic materials (i.e., cable sheaths, PVC flooring, gaskets, seals) and coatings (i.e., paint).

Metizoft has 8 years of industry experience in Ship Recycling and has provided project documentation to about 600 new buildings internationally and collaborating with leading shipyards and ship owners. "There are still a lot of shipping companies that do not know how to handle this, but there is no need to wonder anymore. We have proven on behalf of several major players in the industry that we can handle this. We want to meet the requirements on behalf of ship owners," says Sundgot.

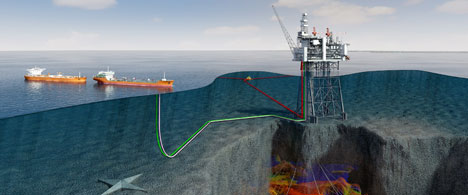

The Ceona Amazon will be deployed for the Coelacanth Export Pipelines project with the scope of work encompassing the installation of an oil and a gas export line tying the new Coelacanth Platform into existing pipeline infrastructure. Each 10" line will be approximately 11 miles, totaling 22.6 miles (approximately 36 km). The pipelines will each be terminated by two pipeline end termination (PLETs) structures installed by the Amazon. All work will be undertaken in one single mobilization.

The Ceona Amazon will be deployed for the Coelacanth Export Pipelines project with the scope of work encompassing the installation of an oil and a gas export line tying the new Coelacanth Platform into existing pipeline infrastructure. Each 10" line will be approximately 11 miles, totaling 22.6 miles (approximately 36 km). The pipelines will each be terminated by two pipeline end termination (PLETs) structures installed by the Amazon. All work will be undertaken in one single mobilization. Subsea 7 S.A.

Subsea 7 S.A.  The five products tankers brought under Crowley Accord management are the MT Dawn Haridwar, MT Dawn Mansarovar (photo), MT Dawn Mathura, MT Dawn Madurai and MT Portland Pearl. The first four are owned by Arya Tankers and will operate along the Indian Coast, while the fifth is owned by Union Maritime Limited and will operate in the Europe-to-Nigeria trade. Combined, these tankers represent over 130,000 gross tons in the market.

The five products tankers brought under Crowley Accord management are the MT Dawn Haridwar, MT Dawn Mansarovar (photo), MT Dawn Mathura, MT Dawn Madurai and MT Portland Pearl. The first four are owned by Arya Tankers and will operate along the Indian Coast, while the fifth is owned by Union Maritime Limited and will operate in the Europe-to-Nigeria trade. Combined, these tankers represent over 130,000 gross tons in the market. N-Sea,

N-Sea,  Mariner Sentinel illustration. (Illustration: Sentinel Marine)

Mariner Sentinel illustration. (Illustration: Sentinel Marine) The Mariner field, located approximately 150 kilometers east of the Shetland Isles, is currently under development, with production start-up planned for 2017. Hook-up and commissioning is expected to start in 2016.

The Mariner field, located approximately 150 kilometers east of the Shetland Isles, is currently under development, with production start-up planned for 2017. Hook-up and commissioning is expected to start in 2016.

MSC Oscar at seatrail. (Image care of MSC)

MSC Oscar at seatrail. (Image care of MSC)

Harvey Gulf International Marine LLC

Harvey Gulf International Marine LLC Photo: The McDermott heavy-lift vessel, Derrick Barge 50, installed a 3,250-ton jacket in the Gulf of Mexico.

Photo: The McDermott heavy-lift vessel, Derrick Barge 50, installed a 3,250-ton jacket in the Gulf of Mexico.

ABS

ABS BMT Nigel Gee Ltd,

BMT Nigel Gee Ltd, Harvey Gulf

Harvey Gulf