The Coastal and Marine Operators (CAMO) group has announced it has successfully completed the first step in rolling out a major initiative to protect the safety of mariners, the environment and hydrocarbon pipelines from being damaged. The CAMO group began transmitting Automatic Information System (AIS) safety messages directly to mariners in two charted pipeline corridors in Port Fourchon, significantly improving their situational awareness by providing immediate alerts for vessels in close proximity to submerged pipelines. These vessel safety messages use existing AIS technology that is already deployed on most commercially operated vessels.

“Pipeline protection is increasingly important, with the typical incident costing an average of at least $1 million to repair, not counting the incalculable costs of injury, death, or environmental impact,” said Ed Landgraf, director of CAMO. “This AIS-based safety broadcasting system culminates several years of hard work on a solution that enables vessel and pipeline operators to collaborate on protecting mariners from the risk of pipeline strikes. The system makes it easier for mariners to know where and when to take protective measures as they transit or operate near submerged pipelines, and we look forward to a successful roll-out here and in other ports nationwide.”

“Pipeline protection is increasingly important, with the typical incident costing an average of at least $1 million to repair, not counting the incalculable costs of injury, death, or environmental impact,” said Ed Landgraf, director of CAMO. “This AIS-based safety broadcasting system culminates several years of hard work on a solution that enables vessel and pipeline operators to collaborate on protecting mariners from the risk of pipeline strikes. The system makes it easier for mariners to know where and when to take protective measures as they transit or operate near submerged pipelines, and we look forward to a successful roll-out here and in other ports nationwide.”

The first phase of CAMO’s AIS-based pipeline damage prevention and awareness program is being launched in partnership with the Greater Lafourche Port Commission (Port Fourchon) and Oceaneering®, a global provider of engineered services and products primarily to the offshore oil and gas industry. Oceaneering’s PortVision® AIS-based vessel-tracking service is being used to monitor vessel activities in the two charted pipeline corridors north and south of Port Fourchon that pass under its main navigable channel. When the PortVision service detects a vessel operating at a speed less than 0.5 knots for three minutes or more within one of these corridors, an addressed, one-time AIS Safety Related Message (also known as message 12) is immediately transmitted directly to the vessel’s wheelhouse that says, “PIPELINE BELOW.”

Depending on the equipment installed on the receiving vessel and its equipment configuration, there may be visual and audible variations in how the AIS safety alert is received. Mariners capable of receiving and displaying the CAMO AIS messages are encouraged to provide feedback and report any anomalies to Oceaneering, Global Data Solutions support at This email address is being protected from spambots. You need JavaScript enabled to view it.or by calling 713-396-8644.

About the CAMO Initiative

CAMO initiated its joint pilot project for marine pipeline damage prevention and awareness in August 2012 with the United States Coast Guard (USCG). The pilot system was developed using Oceaneering’s PortVision AIS-based vessel monitoring service through a grant partnership with Port Fourchon and the Pipeline and Hazardous Materials Safety Administration (PHMSA). The transmission of AIS safety messages has been approved by the FCC and USCG as part of an experimental AIS transmission. The safety message transmission will be operational for 250 days following the USCG notification to mariners recently issued earlier this month. A decision about continuing the transmission will be made after an assessment of how well it has increased vessel operator awareness of subsea infrastructure while reducing the threat of pipeline damage when vessels stop, anchor, drop a spud, or push aground inside one of the designated corridors.

About CAMO

The Coastal and Marine Operators (CAMO) group was developed with a goal to diminish the gap between onshore and offshore spills, releases, and pipeline damage prevention initiatives. A key component of this group’s mission is to educate marine stakeholders and the public about the risks that damage to offshore utilities and pipelines can pose to personal safety and the environment. Although pipeline operators have vigorous inspection and maintenance programs to insure the integrity of their assets, the risk of third-party damage to a pipeline is a continual threat. For more information about CAMO, visit http://www.camogroup.org/ or follow CAMO at https://www.linkedin.com/company/coastal-and-marine-operators-camo-.

The Coastal and Marine Operators (CAMO) group was developed with a goal to diminish the gap between onshore and offshore spills, releases, and pipeline damage prevention initiatives. A key component of this group’s mission is to educate marine stakeholders and the public about the risks that damage to offshore utilities and pipelines can pose to personal safety and the environment. Although pipeline operators have vigorous inspection and maintenance programs to insure the integrity of their assets, the risk of third-party damage to a pipeline is a continual threat. For more information about CAMO, visit http://www.camogroup.org/ or follow CAMO at https://www.linkedin.com/company/coastal-and-marine-operators-camo-.

About Oceaneering’s PortVision Service

PortVision web-based enterprise software and services help oil companies, marine terminal operators, fleet owners/operators and other maritime users improve business operations through instant, continuous visibility into vessel and terminal activities. Based in Houston, Texas, PortVision is a service of Oceaneering International Inc. (NYSE: OII), a global oilfield provider of engineered services and products, primarily to the offshore oil and gas industry, with a focus on deepwater applications. For more information about Oceaneering visit www.oceaneering.com. For more information about PortVision, visit http://www.portvision.com, or follow PortVision on http://www.linkedin.com/company/portvision.

About the Greater Lafourche Port Commission/Port Fourchon

The Greater Lafourche Port Commission, a political subdivision of the state of Louisiana, facilitates the economic growth of the communities in which it operates by maximizing the flow of trade and commerce. We do this to grow our economy and preserve our environment and heritage. The Port Commission exercises jurisdiction over the Tenth Ward of Lafourche Parish, south of the Intracoastal Waterway, including Port Fourchon and the South Lafourche Leonard Miller, Jr. Airport. For more information about Port Fourchon, visit www.portfourchon.com.

Workboats are built for a wide range of purposes. But, they all share the need for trouble-free bushings and bearings. Vesconite offers a line of low-friction, long-lived polymers that thrive in a dirty, marine environment.

Workboats are built for a wide range of purposes. But, they all share the need for trouble-free bushings and bearings. Vesconite offers a line of low-friction, long-lived polymers that thrive in a dirty, marine environment. ACO Marine has been awarded a contract to supply its new Clarimar MF to the CFT 623 wellhead platform

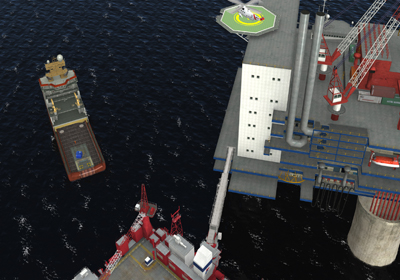

ACO Marine has been awarded a contract to supply its new Clarimar MF to the CFT 623 wellhead platform

The renowned French research vessel, Marion Dufresne II left

The renowned French research vessel, Marion Dufresne II left  The second concept is for a purpose-built, new bunker barge. Offering greater carrying capacity and improved visibility, the design features a larger LNG tank that is nestled inside of the barge. This new barge will also feature the latest safety features and efficiencies.

The second concept is for a purpose-built, new bunker barge. Offering greater carrying capacity and improved visibility, the design features a larger LNG tank that is nestled inside of the barge. This new barge will also feature the latest safety features and efficiencies. Making her debut at the Martin Midstream Dock in Galveston, Texas, Fugro’s premier geophysical survey vessel, the Fugro Americas, was showcased to top clients, with over 100 in attendance.

Making her debut at the Martin Midstream Dock in Galveston, Texas, Fugro’s premier geophysical survey vessel, the Fugro Americas, was showcased to top clients, with over 100 in attendance. A surge in crude tanker vessel capacity over the next two years will lead to a fall in ship-owner earnings from current highs, according to the latest edition of the Tanker Forecaster, published by global shipping consultancy Drewry.

A surge in crude tanker vessel capacity over the next two years will lead to a fall in ship-owner earnings from current highs, according to the latest edition of the Tanker Forecaster, published by global shipping consultancy Drewry. Crowley Maritime Corp.’s

Crowley Maritime Corp.’s  “Pipeline protection is increasingly important, with the typical incident costing an average of at least $1 million to repair, not counting the incalculable costs of injury, death, or environmental impact,” said Ed Landgraf, director of CAMO. “This AIS-based safety broadcasting system culminates several years of hard work on a solution that enables vessel and pipeline operators to collaborate on protecting mariners from the risk of pipeline strikes. The system makes it easier for mariners to know where and when to take protective measures as they transit or operate near submerged pipelines, and we look forward to a successful roll-out here and in other ports nationwide.”

“Pipeline protection is increasingly important, with the typical incident costing an average of at least $1 million to repair, not counting the incalculable costs of injury, death, or environmental impact,” said Ed Landgraf, director of CAMO. “This AIS-based safety broadcasting system culminates several years of hard work on a solution that enables vessel and pipeline operators to collaborate on protecting mariners from the risk of pipeline strikes. The system makes it easier for mariners to know where and when to take protective measures as they transit or operate near submerged pipelines, and we look forward to a successful roll-out here and in other ports nationwide.” The Coastal and Marine Operators (CAMO) group was developed with a goal to diminish the gap between onshore and offshore spills, releases, and pipeline damage prevention initiatives. A key component of this group’s mission is to educate marine stakeholders and the public about the risks that damage to offshore utilities and pipelines can pose to personal safety and the environment. Although pipeline operators have vigorous inspection and maintenance programs to insure the integrity of their assets, the risk of third-party damage to a pipeline is a continual threat. For more information about CAMO, visit

The Coastal and Marine Operators (CAMO) group was developed with a goal to diminish the gap between onshore and offshore spills, releases, and pipeline damage prevention initiatives. A key component of this group’s mission is to educate marine stakeholders and the public about the risks that damage to offshore utilities and pipelines can pose to personal safety and the environment. Although pipeline operators have vigorous inspection and maintenance programs to insure the integrity of their assets, the risk of third-party damage to a pipeline is a continual threat. For more information about CAMO, visit  Its state-of-the-art industrial equipment will be powered entirely by renewable energy. An electrically powered crane that uses fly wheel technology to capture, store and then return power as needed, the crane will run on electricity provided by the Kodiak Electric Association, which uses wind and water turbines to generate 99.9 percent of its power. (See the technology in action here:

Its state-of-the-art industrial equipment will be powered entirely by renewable energy. An electrically powered crane that uses fly wheel technology to capture, store and then return power as needed, the crane will run on electricity provided by the Kodiak Electric Association, which uses wind and water turbines to generate 99.9 percent of its power. (See the technology in action here:

The vessel comes fitted with a new build 18-man self-propelled hyperbaric lifeboat (SPHL) for evacuation of the divers under saturation in case of an emergency. This SPHL can be coupled with a newly built and dedicated portable hyperbaric rescue facility (HRF) to ensure safe decompression of divers.

The vessel comes fitted with a new build 18-man self-propelled hyperbaric lifeboat (SPHL) for evacuation of the divers under saturation in case of an emergency. This SPHL can be coupled with a newly built and dedicated portable hyperbaric rescue facility (HRF) to ensure safe decompression of divers.