The horrific explosions in the Chinese port of Tainjin illustrated vividly just how volatile port operations can be. But safety issues are only one facet of risk in the complex world of shipping ports.

The horrific explosions in the Chinese port of Tainjin illustrated vividly just how volatile port operations can be. But safety issues are only one facet of risk in the complex world of shipping ports.

From piracy on the high seas to data thievery in port, players all along the shipping value chain need to be on constant alert for the dangers that nature and human actions can present.

Political unrest, theft, smuggling and corruption all figure in to the risk picture that ship owners, brokers, and cargo owners have to consider when planning and executing port calls. “The security picture can change quickly at ports,” says an Oslo-based global cruise operator. “We call around the world, and not always at the largest or most modern ports, so we have to be aware of the whole risk picture in order to guarantee our passengers’ safety.”

Another shipowner, a leading global tanker owner operating out of Copenhagen, confers: “We had an armed robbery just the other day,” he reports. “If we know the risk picture in advance, we can take preventative measures, like putting more guards on watch. If we don’t know beforehand, we are vulnerable.”

Port operations are often exposed when the stability of a country is compromised. Ports are choke points for transportation of energy, food and materials, and the normal functioning of a country can depend on safe operations in key ports.

For cruise operators, ports could be attractive targets for kidnapping, smuggling, theft or even terrorism. “We plan our routes as much as two years in advance,” the cruise owner confirms, “so things can change dramatically from planning to sailing. We basically have to monitor the situation in every port of call on a day-to-day basis.”

The tanker operator points out that the master is not capable of assessing risk on his own. “We have to call an agent, and they generally give us a copy-paste reply that is of little or no help.” In addition an agent generally has no opportunity to provide a security assessment, including standards at the gate, or the state of the local police.

While cruise lines play it as safely as possible, tanker operators call on some of the riskiest ports in the business, in West Africa, Indonesia, and South America. “There are some clauses in the contract that allow us to avoid the most dangerous situations, like armed conflict, but we still have to deal with stowaways, theft, and more in many of our ports of call.”

As if physical threats were not enough to put grey hair on shipowner heads, a new risk has emerged – in cyber space. Information technology has become an integral part of port and ship operations, but ICT systems in the shipping world are not always designed with cyber safety in mind. Hackers can alter or jam the Automatic Identification System (AIS) that tracks hips at sea, and the ISPS code that ensures physical port safety only marginally addresses the threat of cyber attack.

Matt Haworth, a Cyber and Information Assurance Specialist with cyber advice service provider Templar Executives believes that cyber security is now one of the most complex threats faced by the maritime industry and its critical infrastructure. “Ports and terminals are under attack from cyber criminals, organised crime and terrorist groups looking to disrupt national infrastructure and hostile governments,” he says.

So how dangerous does it have to get before shipowners just say no? Most shipowners would agree that it depends on the risk profile that owners carry. Cruise operators have a very low risk threshold because they can take no chances with their human cargo. For others, certain risk factors are acceptable, but everyone has a limit.

In any case, it is up to ship and cargo owners to decide how much risk they are willing to take. The one thing they can do is be as informed as possible. No one can guarantee safety, but knowing risk is the key to making the decisions that are right for shipowners, their crew, and their cargo.

CEO Hans Tino Hansen of Risk Intelligence, suppliers of the popular MaRisk security threat monitoring service, offers his take on the current state of port risk:

“We follow the development of risk in ports closely, and we are seeing a clear trend toward an increasingly critical and more complex global port risk picture.

Our customers operate more than 12% of the world fleet. They see the same picture, and in response, they have told us they need a one-stop port risk advisory service. Right now they have to access many channels to get port risk information, and they find the information they are getting is often unreliable.

The industry has a pressing need for a single, easily accessible channel for comprehensive and reliable intelligence on risk in ports. Providing that solution will be our main priority going forward.”

For more information contact:

Hans Tino Hansen

Managing Director & CEO

About Risk Intelligence

Risk Intelligence provides independent, unbiased, intelligence-led advisory services to private and governmental clients on security threats and risks.

Risk Intelligence has been specialising in analysing threats from and interaction between piracy, organised crime, terrorism, insurgency and military conflicts since 2003.

Read more on our website: www.riskintelligence.eu

Tuesday 20 October 2015, BigLift Shipping’s heavy-lift vessel Happy Star arrived in the Port of Rotterdam. This is the first time Happy Star has visited the Netherlands, bringing with her

Tuesday 20 October 2015, BigLift Shipping’s heavy-lift vessel Happy Star arrived in the Port of Rotterdam. This is the first time Happy Star has visited the Netherlands, bringing with her  Two recent events have highlighted how the

Two recent events have highlighted how the

RigNet, Inc.

RigNet, Inc. Imtech Marine signed during the World Port Days 2015 in Rotterdam for a prolonged stay at the RDM Innovation Dock. From left to right Mark Linde (Global Director Design Technology & Engineering) on behalf of Imtech Marine and Angelien Sanderman (Member of the Board) on behalf of Rotterdam University of Applied Sciences.

Imtech Marine signed during the World Port Days 2015 in Rotterdam for a prolonged stay at the RDM Innovation Dock. From left to right Mark Linde (Global Director Design Technology & Engineering) on behalf of Imtech Marine and Angelien Sanderman (Member of the Board) on behalf of Rotterdam University of Applied Sciences. The horrific explosions in the Chinese port of Tainjin illustrated vividly just how volatile port operations can be. But safety issues are only one facet of risk in the complex world of shipping ports.

The horrific explosions in the Chinese port of Tainjin illustrated vividly just how volatile port operations can be. But safety issues are only one facet of risk in the complex world of shipping ports. The World Ocean Council (WOC)

The World Ocean Council (WOC) Willard Marine

Willard Marine Damen Shipyards Group

Damen Shipyards Group Gulf Coast Shipyard Group (GCSG)

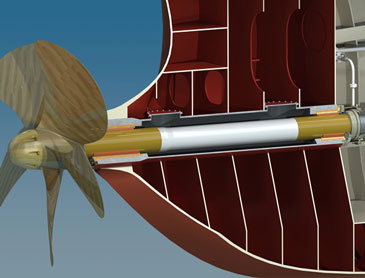

Gulf Coast Shipyard Group (GCSG) Thordon Bearings’

Thordon Bearings’ As offshore oil exploration and production expands, the need for high speed spill response vessels has increased. G.M. Penman is

As offshore oil exploration and production expands, the need for high speed spill response vessels has increased. G.M. Penman is  OEG Offshore-John Heiton

OEG Offshore-John Heiton Sea Trucks

Sea Trucks Fugro Scout

Fugro Scout On Friday 11 September, the Wei-Li crane ship slipped her lines at

On Friday 11 September, the Wei-Li crane ship slipped her lines at  The liftboat was designed and built by SEMCO, a well known and highly regarded liftboat builder. It is equipped with two 175-ton leg mounted cranes and a large open deck to assist in carrying equipment and supplies in support of various offshore activities. The vessel can accommodate 50 people, including private rooms dedicated for customer representatives.

The liftboat was designed and built by SEMCO, a well known and highly regarded liftboat builder. It is equipped with two 175-ton leg mounted cranes and a large open deck to assist in carrying equipment and supplies in support of various offshore activities. The vessel can accommodate 50 people, including private rooms dedicated for customer representatives.