New vessel with walk-to-work functionality purpose-built for offshore wind operations

On 15 January, Bibby Marine Services Limited, part of Bibby Line Group, signed a contract with the Damen Shipyards Group for delivery of its first Service Operations Vessel (SOV) with walk-to-work access. The vessel, Bibby WaveMaster 1, will undertake offshore wind project work in the North Sea. It is the first vessel purpose-built for the transfer and accommodation of offshore personnel and aims to maximise working time and staff retention. The design guarantees fast, safe and comfortable access to turbines, at lower cost, up to 80% of the time, including in worst case scenario Central North Sea conditions, resulting in a vessel capable of providing access up to 3.1 meter Hs.

On 15 January, Bibby Marine Services Limited, part of Bibby Line Group, signed a contract with the Damen Shipyards Group for delivery of its first Service Operations Vessel (SOV) with walk-to-work access. The vessel, Bibby WaveMaster 1, will undertake offshore wind project work in the North Sea. It is the first vessel purpose-built for the transfer and accommodation of offshore personnel and aims to maximise working time and staff retention. The design guarantees fast, safe and comfortable access to turbines, at lower cost, up to 80% of the time, including in worst case scenario Central North Sea conditions, resulting in a vessel capable of providing access up to 3.1 meter Hs.

In line with wind farms being constructed farther from shore, the SOV with walk-to-work access is able to remain at sea for periods up to one month. Accommodation is provided on board for up to 45 turbine maintenance personnel and 15 crew members.

Dedicated to the job in hand

Damen Business Development Manager Peter Robert described the thinking behind the concept, saying, “This is much more than just a vessel – it is a total access and accommodation solution. The development of this vessel has started with a blank sheet of paper, as opposed to being an evolved version of an existing design. It has been tailored specifically to the needs of the offshore wind industry. This is the first time that a wind farm operations and maintenance vessel has been designed exclusively for this purpose. Great care has been taken, over 2 years of development, to ensure suitability to the tasks for which it is designed.

“As a result, the vessel will ensure the safety and comfort of all on board for increased workability. This, in combination with other design features aiming at optimal workflow, ensures that the Service Operations Vessel offers a revolutionary performance in terms of cost-efficiency.

“We are delighted to be working with one of the great names in shipping. Damen and Bibby both have a strong maritime heritage and, almost uniquely, are both still family owned. However, both companies are clearly focussed on innovation and by working together, we are strengthening our position in the offshore renewables sector.”

The attention to detail can be seen throughout the design. For example, the hull, at 90 meters, is longer than that of a conventional platform supply vessel and the bow section has been lowered by 1.5 meters to create a V-shape. This feature offers significantly reduced slamming and facilitates inclusion and improved offshore operation of the bow thrusters.

The aft ship has been adapted specifically to the tasks that the vessel is designed for, including stern to waves operations. The most pronounced features that have been included are the strong V-shape in the frames in the aft ship to reduce the slamming occurrence and loads and the concentration of volume in the mid-ship region to achieve a slender aft ship. Both features should make stern to weather operations more comfortable than on a common PSV design.

Comfort onboard stems also from ergonomic design application, which sees interior spaces grouped together into similar task areas. This not only separates ‘clean’ and ‘dirty’ tasks, but ensures short lines of communication and smooth workflow. The accommodation has been placed midships for additional comfort – the location reducing vertical acceleration by as much as 15%.

Efficiency is another key feature. The design includes a diesel-electric main propulsion system, which powers twin azimuth thrusters. Thanks to careful development, the vessel requires less installed power than a conventional PSV. This results from two factors – a symmetrical wind profile and use of a four split main switchboard.

Mr. Robert: “The symmetric profile is created by locating the superstructure amidships instead of bow mounted. Because of this, the wind induced moment is less, resulting in lower required bow thruster power. The four split configuration of the main switchboard enables us to divide the generator sets more efficiently than in conventional arrangements with two switchboards. In the event of a failure only one of four switchboards would be out of action, as opposed to one of two. That leaves proportionally more power available, again requiring less total installed power.”

A high-performance, motion-compensated access gangway and active heave compensated crane are located to port side, close to the centre of gravity. The management systems of both features are aligned with the vessel’s DP system.

Proven to Master the weather

The DP capabilities have already been proven, with a first-of-its-kind scale model test at the Netherlands-based leading research institute, MARIN. During these tests, the scale model of the vessel was pitted against North Sea wind, wave, swell and current simulations.

The target was a 30-minute cycle, during which the vessel deploys the gangway and then transits in AutoTrack mode, several hundred metres, at speeds up to and beyond 6 knots to the following turbine without having to wait for an ideal weather window or having to rebuild the DP model at every turbine.

Strong performance was confirmed by Lead Engineer DP & Manoeuvring Product at DP provider Kongsberg, Audun Bjarte Navelsaker: “Damen’s vessel performed very well and was very stable during different types of weather. To my knowledge, this was the first test where we could control the weather and external factors acting on a vessel.”

The vessel exceeded all expectations, as Dr Joop Helder, MARIN Project Manager Offshore attested: “The results clearly showed Damen’s vessel performing very nicely. Especially in the wave conditions – there was hardly any rolling. I think these tests give a lot of confidence.”

Flexible & versatile

The vessel will be used by Bibby Marine Services to serve the offshore wind industry although the design can just as easily be applied to the offshore oil and gas sectors.

A host of options are available for the vessel, including an additional deck crane with up to 24 tonnes capability, tanks arrangements suited to liquids such as glycols, tanks suited to low flashpoint liquids with separate delivery intakes and facilities for dive support and ROV operations.

Stephen Blaikie, Chief Executive Officer, Bibby Marine Services Ltd. Commented, “We have worked very closely with Damen to custom design an access and accommodation solution that exactly meets the specific needs of wind farm operators. Bibby WaveMaster 1 will operate with the greenest possible credentials. It is designed to give operators more access, more safety and more comfort when operating and servicing their wind farms.”

Bibby Marine Services Limited

Bibby Marine Services Limited is a wholly owned subsidiary of Bibby Line Group Limited and has the express aim of serving the marine needs of the offshore renewables market.

Bibby WaveMaster 1 is the first vessel to be commissioned by Bibby Marine Services Limited. Its key features are:

• Offshore transfers for special personnel and equipment by means of a motion compensated access system and heave compensated offshore rated knuckle boom crane on a stable DP-2 vessel platform

• 90m LOA

• Comfort Class 2 accommodation - 60 individual ensuite berths

• Helipad

• Class-leading leisure facilities

• Daughter craft and CTV landings

On 4 February 2016 the DP2 cable installation vessel Maersk Connector was handed over from

On 4 February 2016 the DP2 cable installation vessel Maersk Connector was handed over from  ABB, a leading power and automation technology group, will provide the technology that will help three vessels safely carry out construction and maintenance tasks up to 5 kilometers under water. The vessels will be equipped with ABB’s OCTOPUS software that uses sensors and the Internet of Things, Services and People (IoTSP) to interpret weather conditions, allowing the crew to make informed decisions during sensitive operations. The ships will be built for Ultra Deep Solutions at CSIC Huangpu Wuchang Shipbuilding Company Limited and China Merchants Heavy Industry.

ABB, a leading power and automation technology group, will provide the technology that will help three vessels safely carry out construction and maintenance tasks up to 5 kilometers under water. The vessels will be equipped with ABB’s OCTOPUS software that uses sensors and the Internet of Things, Services and People (IoTSP) to interpret weather conditions, allowing the crew to make informed decisions during sensitive operations. The ships will be built for Ultra Deep Solutions at CSIC Huangpu Wuchang Shipbuilding Company Limited and China Merchants Heavy Industry. Modal Training, the first organization in the UK to offer integrated, multimodal logistics training, has invested in a full suite of advanced ship, offshore vessel, engine room and radar simulators from

Modal Training, the first organization in the UK to offer integrated, multimodal logistics training, has invested in a full suite of advanced ship, offshore vessel, engine room and radar simulators from  Tidewater Subsea charters the Jones Act compliant MV

Tidewater Subsea charters the Jones Act compliant MV  MacGregor, part of Cargotec, can now offer the offshore industry a technology-leading fiber-rope crane. The crane has been developed by combining MacGregor's proven offshore crane technology with the fiber-rope tensioning technology perfected by Parkburn Precision Handling Systems. The companies have entered into a cooperation agreement to combine MacGregor's offshore crane expertise with Parkburn's fiber-rope tensioning technology.

MacGregor, part of Cargotec, can now offer the offshore industry a technology-leading fiber-rope crane. The crane has been developed by combining MacGregor's proven offshore crane technology with the fiber-rope tensioning technology perfected by Parkburn Precision Handling Systems. The companies have entered into a cooperation agreement to combine MacGregor's offshore crane expertise with Parkburn's fiber-rope tensioning technology. Oceaneering’s Maritime Business Systems

Oceaneering’s Maritime Business Systems Event attendees will see live PortVision 360 demonstrations and learn about enhanced alerting and reporting capabilities that can be customized for information sharing and collaboration. Oceaneering will also host exclusive sessions with key customers and industry stakeholders during the day, focused on critical issues facing marine terminal management and marine pipeline protection.

Event attendees will see live PortVision 360 demonstrations and learn about enhanced alerting and reporting capabilities that can be customized for information sharing and collaboration. Oceaneering will also host exclusive sessions with key customers and industry stakeholders during the day, focused on critical issues facing marine terminal management and marine pipeline protection. Eliminating the slack line required for conventional tie-ups,

Eliminating the slack line required for conventional tie-ups,  Kongsberg Maritime’s

Kongsberg Maritime’s Crowley Maritime Corporation’s

Crowley Maritime Corporation’s  Bordelon Marine

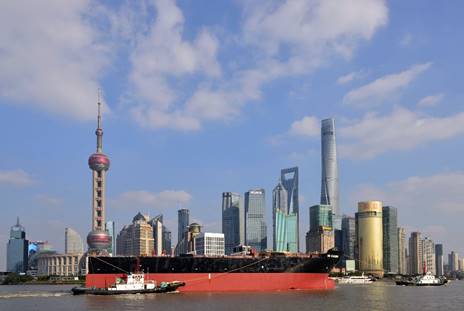

Bordelon Marine The second edition of Seawork Asia will open its doors 29 November in Shanghai. It is the fastest growing commercial marine and workboat exhibition in the East Asian region, located at the heart of this fast growing industry sector.

The second edition of Seawork Asia will open its doors 29 November in Shanghai. It is the fastest growing commercial marine and workboat exhibition in the East Asian region, located at the heart of this fast growing industry sector. On 15 January,

On 15 January,  “We don’t usually remove the heads at mid-life on the Cummins engines,” Randy Beckler, Shore Engineer for

“We don’t usually remove the heads at mid-life on the Cummins engines,” Randy Beckler, Shore Engineer for  These two boats have been very popular with their crews. The hulls were built to order in China, shipped to Canada by barge, and finished up at Seaspan’s Vancouver Shipyard. There was a lot of input from operators in the functional design. At the time they were a new generation of tug with a fine, longer, double-chined hull. The 64- by 23-foot hull has a moulded depth held to 10.4-feet to facilitate working some of the shallower areas of the lower Fraser River while providing good water flow to the propellers. This fine hull form, combined with a smooth "slipper" stern reduced the wake wash and lessoned the need for the tug to make a "slow-bell" past riverside moorings.

These two boats have been very popular with their crews. The hulls were built to order in China, shipped to Canada by barge, and finished up at Seaspan’s Vancouver Shipyard. There was a lot of input from operators in the functional design. At the time they were a new generation of tug with a fine, longer, double-chined hull. The 64- by 23-foot hull has a moulded depth held to 10.4-feet to facilitate working some of the shallower areas of the lower Fraser River while providing good water flow to the propellers. This fine hull form, combined with a smooth "slipper" stern reduced the wake wash and lessoned the need for the tug to make a "slow-bell" past riverside moorings. MacGregor, part of Cargotec, has strengthened its position in the heavy-lift market by confirming an important new contract to deliver twelve 450-ton capacity heavy-lift cranes for six Ecolift F900 vessels. The 13,300 dwt vessels are being built by two Chinese shipyards, Hudong and Huangpu Wenchong, for long-term charter to US operator Intermarine. Options remain for a further four vessels. The order was booked into fourth quarter 2015 order intake.

MacGregor, part of Cargotec, has strengthened its position in the heavy-lift market by confirming an important new contract to deliver twelve 450-ton capacity heavy-lift cranes for six Ecolift F900 vessels. The 13,300 dwt vessels are being built by two Chinese shipyards, Hudong and Huangpu Wenchong, for long-term charter to US operator Intermarine. Options remain for a further four vessels. The order was booked into fourth quarter 2015 order intake. Harding

Harding CASCADe, a three-year, EU-funded project which is coming to a close this month has developed new methodologies in which information is shared and displayed on a ship’s bridge, helping to improve efficiency on board and contribute towards the prevention of accidents at sea.

CASCADe, a three-year, EU-funded project which is coming to a close this month has developed new methodologies in which information is shared and displayed on a ship’s bridge, helping to improve efficiency on board and contribute towards the prevention of accidents at sea.