Decom North Sea (DNS), the representative body for the decommissioning industry, commissions and facilitates projects that deliver meaningful benefits for its members and improves the efficiency of future of decommissioning activities.

Decom North Sea (DNS), the representative body for the decommissioning industry, commissions and facilitates projects that deliver meaningful benefits for its members and improves the efficiency of future of decommissioning activities.

This week, DNS has announced a partnership with Zero Waste Scotland (ZWS) and subsea engineering and training firm, Jee Ltd, which will investigate efficient solutions for the recovery of concrete subsea mattresses and re-use, thereby contributing to the circular economy.

The project involves engaging with operators and suppliers across the oil and gas industry, with both DNS and Jee's expert engineers conducting an economic and environmental assessment of the condition of the mattresses, and identifying the best techniques for their recovery.

The project involves engaging with operators and suppliers across the oil and gas industry, with both DNS and Jee's expert engineers conducting an economic and environmental assessment of the condition of the mattresses, and identifying the best techniques for their recovery.

Nigel Jenkins, CEO of DNS looks forward to this project getting underway: "This project was implemented in direct response to our operator member requests. What to do with mattresses as part of an efficient decommissioning solution is an often discussed "thorny" issue. Leaving them in situ is not ordinarily an option, although we will revisit this. Mattresses were not specifically designed to be removed. Unfortunately, they can degrade underwater over time, leading to a complicated and costly removal process during decommissioning."

Building on previous collaboration with Zero Waste Scotland, DNS has selected Jee, through a competitive tender process, to challenge current thinking and uncover the efficient removal methods that can reduce costs and maximise decommissioning sector benefits from the implementation of circular economy principles. These principles ensure that materials are retained within productive use, in a high value state, for as long as possible – a succinct illustration of DNS' fundamental objective to drive effective and efficient decommissioning activity which will ultimately benefit the oil and gas industry, the environment and the UK tax payer.

Dean Kirby, Senior Engineer at Jee Ltd said: "Millions of pounds are being spent on UKCS decommissioning each year, and this will continue for several decades. As with the majority of decommissioning projects, the recovery and disposal of subsea mattresses presents a significant obstacle and financial burden to operators and contractors globally.

"There is a need for a safe, quick and cost effective system for mattress removal, and at Jee we strive to identify and develop the best solutions for the industry."

Iain Gulland, Chief Executive of Zero Waste Scotland said: "The circular economy is becoming increasingly prominent nationally, because of the economic opportunities and environmental benefits it presents. This ambitious project to recover and re-use deep sea mattresses is a great example of the sort of innovative thinking currently happening in Scotland."

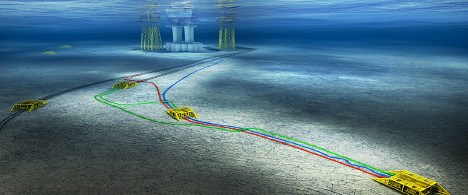

Concrete mattresses provide pipelines, cables and umbilicals with protection from dropped objects, and add weight and stabilisation. Jee's analysis will identify the potential reuse and circular economy applications for the mattresses, as well as highlighting guidance on best practice for recovery and key points for derogation cases to leave in situ.

Project findings will be delivered through an industry report and presentation via DNS later this year.

Asset Guardian Solutions Ltd

Asset Guardian Solutions Ltd GAC Managing Director Gobind Kukreja shows off the company's latest ISO Certification.

GAC Managing Director Gobind Kukreja shows off the company's latest ISO Certification. Petrofac's JSD 6000 new vessel complements McDermott's global fleet as it offers top-tier functionality for a wide range of ultra-deepwater pipelay, subsea lowering and above surface construction work, through its combined J-lay, S-lay and ultra-heavy lift capabilities. (Photo: Business Wire)

Petrofac's JSD 6000 new vessel complements McDermott's global fleet as it offers top-tier functionality for a wide range of ultra-deepwater pipelay, subsea lowering and above surface construction work, through its combined J-lay, S-lay and ultra-heavy lift capabilities. (Photo: Business Wire) On 21 February

On 21 February  International oil and gas support services company

International oil and gas support services company Wood Group Kenny (WGK)

Wood Group Kenny (WGK) View in to the dome simulator that virtually resembles the drill floor - Courtesy of Maersk Training

View in to the dome simulator that virtually resembles the drill floor - Courtesy of Maersk Training

Decom North Sea (DNS),

Decom North Sea (DNS), The project involves engaging with operators and suppliers across the oil and gas industry, with both DNS and Jee's expert engineers conducting an economic and environmental assessment of the condition of the mattresses, and identifying the best techniques for their recovery.

The project involves engaging with operators and suppliers across the oil and gas industry, with both DNS and Jee's expert engineers conducting an economic and environmental assessment of the condition of the mattresses, and identifying the best techniques for their recovery. Unique Maritime Group (UMG)

Unique Maritime Group (UMG) Aker Solutions

Aker Solutions  New Industries, Inc.

New Industries, Inc. The reserve replacement ratio was 146%. For each barrel produced, the company added 1.46 barrels to its reserves.

The reserve replacement ratio was 146%. For each barrel produced, the company added 1.46 barrels to its reserves.