Harding extended its string of offshore successes with contracts for deliveries of lifeboats and davits to the Culzean offshore gas complex, to be constructed for owner Maersk Oil UK by Sembcorp Marine subsidiary SMOE PteLtd of Singapore.

Harding extended its string of offshore successes with contracts for deliveries of lifeboats and davits to the Culzean offshore gas complex, to be constructed for owner Maersk Oil UK by Sembcorp Marine subsidiary SMOE PteLtd of Singapore.

The Culzean win gives Harding a sweep of the latest big offshore contracts, including deliveries of lifeboats and davits to the Heerema heavy lift semisubmersible crane Sleipnir and to the giant Johan Sverdrup field center.

"We have worked hard to strengthen our position in today's difficult offshore market," says Harding's global director of sales Bjørn Sturle Hillestad. "Winning the Culzean project was a key strategic goal in this process."

Culzean is one of the largest gas discoveries of recent years in the UK North Sea, and the field center will comprise a 12-slot wellhead platform (WHP) linked by bridges to a central processing facility (CPF) supported by a floating storage and offloading vessel (FSO), and an installation for utilities and living quarters (ULQ).

Harding will deliver three FF1200 lifeboats to the ULQ and one FF1200 to the WHP, both with LA1200SU davits. The davits are scheduled for delivery by March 2017, with the lifeboats to follow in December of the same year. The WHP/FSO contract is still in bid phase.

The FF1200 is a 70-person freefall lifeboat designed to meet the most stringent standards in the industry, and with just more than 100 delivered, it is among the most popular in the industry. The LA1200SU is a skid-launch davit specially designed for the FF1200.

“Competition isn’t getting any easier, so we are very happy and proud to have won these latest contracts,” reports Harding Regional Sales Director Odd Åge Helvik.

Harding attributes its success to a combination of high quality, a strong local presence, and central expertise.

“We have our eyes and ears in Singapore, and that allows us to respond quickly to openings, and establish good contacts with the owner and the yard,” Helvik says. “Then we mobilize the technical team to tailor deliveries to the customer’s requirements.”

Communication is king

Bjørn Sturle Hillestad, Harding’s Global Sales and Marketing Director, emphasises that good communications are key in winning good contracts. “Our first job is to earn customer confidence, to build their trust in Harding quality, and we have plenty of good references to help us there,” he relates. “Then we listen. We learn about their concerns and preferences, and help them to understand that we are committed to delivering exactly what they need, not just a standard product line.”

Hillestad also want to emphasise the value of a true team effort: “No one person is responsible for our success. We are a global team, and we believe the customers see the advantage of this.”

In a tough market, though, continued success is never guaranteed. “We are bucking the current right now,” Odd Åge Helvik acknowledges. “We realise the only way to maintain success is to keep delivering quality, and keep giving the customer what they really want.”

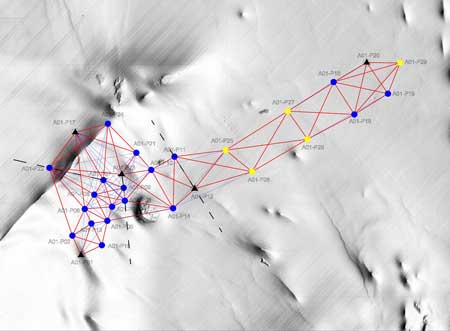

LBL acoustic positioning networks provide ultra-accurate subsea positioning at Kaombo development

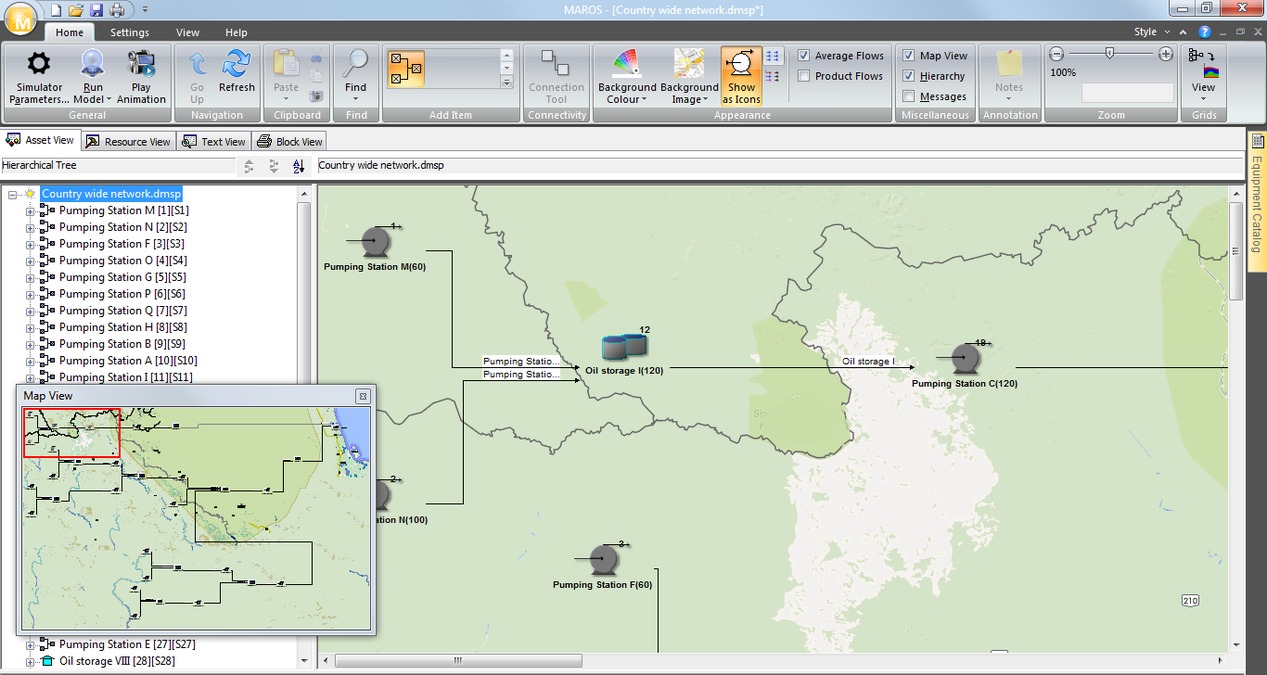

LBL acoustic positioning networks provide ultra-accurate subsea positioning at Kaombo development With profit margins under pressure, oil and gas companies are focused on getting more out of existing assets while significantly reducing capital expenditure. Recent data shows that a 5% improvement in Opex could save £490 million on the UK Continental Shelf alone. The new DNV GL release of Maros and Taro software provides powerful tools to support these improvements.

With profit margins under pressure, oil and gas companies are focused on getting more out of existing assets while significantly reducing capital expenditure. Recent data shows that a 5% improvement in Opex could save £490 million on the UK Continental Shelf alone. The new DNV GL release of Maros and Taro software provides powerful tools to support these improvements. In London,

In London,  Harding extended its string of offshore successes with contracts for deliveries of lifeboats and davits to the Culzean offshore gas complex, to be constructed for owner Maersk Oil UK by Sembcorp Marine subsidiary SMOE PteLtd of Singapore.

Harding extended its string of offshore successes with contracts for deliveries of lifeboats and davits to the Culzean offshore gas complex, to be constructed for owner Maersk Oil UK by Sembcorp Marine subsidiary SMOE PteLtd of Singapore. Rolls-Royce

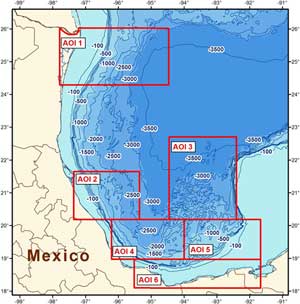

Rolls-Royce Location of areas covered by CGG’s multi-client airborne gravity and magnetic survey offshore Mexico.

Location of areas covered by CGG’s multi-client airborne gravity and magnetic survey offshore Mexico. Image courtesy: Wärtsilä

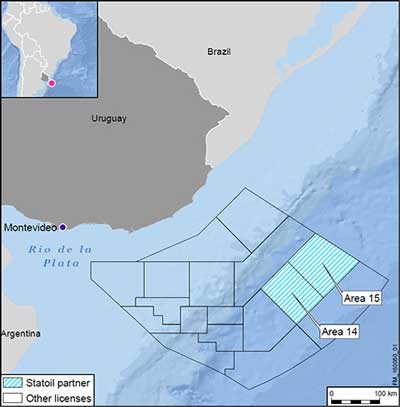

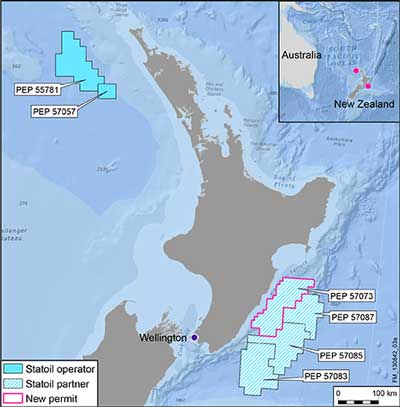

Image courtesy: Wärtsilä Map Image : Courtesy Statoil

Map Image : Courtesy Statoil The Signature55 gives oil and gas customers flexible access to long range profiling capability.

The Signature55 gives oil and gas customers flexible access to long range profiling capability. All American Marine, Inc. (AAM)

All American Marine, Inc. (AAM) Harvey Gulf

Harvey Gulf Image Courtesy: SMSC

Image Courtesy: SMSC Statoil

Statoil Tracking and interpreting threats is now easier than ever with the DRS4D-NXT Radar. Using Furuno’s advanced Doppler technology, this new Radar acquires and tracks targets in virtually every sweep, or just a few seconds. Almost instantly, you will see the target’s speed and course vector. If the target is hazardous, it will also be displayed in red, making it easier to identify and predict its course. The NXT Radar’s incredible ARPA signal processor will display and track up to 100 targets in a single sweep! The entire target theatre can be viewed, monitored, and tracked simultaneously, at any range. For an even more detailed display, target trails and Furuno’s unique True Trail feature can be utilized, allowing you to graphically see the direction in which a target is moving, independent of your own vessel’s motion.

Tracking and interpreting threats is now easier than ever with the DRS4D-NXT Radar. Using Furuno’s advanced Doppler technology, this new Radar acquires and tracks targets in virtually every sweep, or just a few seconds. Almost instantly, you will see the target’s speed and course vector. If the target is hazardous, it will also be displayed in red, making it easier to identify and predict its course. The NXT Radar’s incredible ARPA signal processor will display and track up to 100 targets in a single sweep! The entire target theatre can be viewed, monitored, and tracked simultaneously, at any range. For an even more detailed display, target trails and Furuno’s unique True Trail feature can be utilized, allowing you to graphically see the direction in which a target is moving, independent of your own vessel’s motion. The Bureau of Ocean Energy Management (BOEM), National Oceanic and Atmospheric Administration (NOAA), and the U.S. Geological Survey (USGS) announced that the National Oceanographic Partnership Program (NOPP) will present the

The Bureau of Ocean Energy Management (BOEM), National Oceanic and Atmospheric Administration (NOAA), and the U.S. Geological Survey (USGS) announced that the National Oceanographic Partnership Program (NOPP) will present the  CSA provides mission critical support to complex offshore operations for both private sector and governmental agencies around the global. As the project’s prime contractor, CSA managed the team through several years of field research and subsequent analysis and reporting. The team included staff from BOEM, USGS, NOAA’s Office of Ocean Exploration and Research, and a dozen universities and research institutions. A CSA Senior Scientist also served as Co-Chief Scientist on multiple segments of the program’s research cruises.

CSA provides mission critical support to complex offshore operations for both private sector and governmental agencies around the global. As the project’s prime contractor, CSA managed the team through several years of field research and subsequent analysis and reporting. The team included staff from BOEM, USGS, NOAA’s Office of Ocean Exploration and Research, and a dozen universities and research institutions. A CSA Senior Scientist also served as Co-Chief Scientist on multiple segments of the program’s research cruises. HARKAND

HARKAND