Ballast water treatment (BWT) specialist Optimarin has cemented its place at the vanguard of the market, with the news that it has now sold over 400 of its environmentally friendly UV-based systems. The landmark has been surpassed on the back of a succession of major contracts, fuelled by the firm’s unique retrofit experience, proven technology and upcoming USCG certification.

Ballast water treatment (BWT) specialist Optimarin has cemented its place at the vanguard of the market, with the news that it has now sold over 400 of its environmentally friendly UV-based systems. The landmark has been surpassed on the back of a succession of major contracts, fuelled by the firm’s unique retrofit experience, proven technology and upcoming USCG certification.

2016 has been a boom year for a company that installed the first ever commercial BWT system back in 2000. Optimarin Ballast System (OBS) orders have been confirmed with Atlantis Tankers (10 units) and Sinopacific Shipbuilding Group (nine), while the firm also made its first foray into fishing, with a contract for the Fisherman’s Finest vessel America’s Finest. The latest win, with Carisbrooke from the UK, was the largest - a fleet agreement with the potential to encompass retrofits on 46 bulk and multipurpose vessels.

“We’ve been working with BWT technology since our formation in 1994,” comments Optimarin CEO Tore Andersen, “so we feel this surge in business reflects an appreciation of our established expertise, technology, and ability to satisfy all individual customer, and vessel, requirements.

“Now that the ratification of the IMO’s Ballast Water Management convention is finally imminent, we’re seeing more and more shipowners engaging us for fleet wide retrofit assignments. This is because they know they can trust us, our market proven system, and unparalleled retrofit experience.”

Together with its global engineering partners, Goltens and Zeppelin, Optimarin has now fitted over 70 units on existing vessels, alongside over 200 on newbuilds. Its flexible, modular system is perfect for making the most of limited vessel space, while its totally compliant technology ensures peace of mind.

This latter point has proven to be another of Optimarin’s strengths. The firm has invested millions of dollars in testing and certification, with certificates from DNV GL, Lloyd’s, Bureau Veritas, MLIT Japan, and American Bureau of Shipping, alongside full IMO approval. However, it’s the latest testing with USCG that appears to be elevating the business to a new commercial plane.

“USCG has the most stringent approval demands, thanks to its FDA/CMFDA test, which judges the life forms transported in ballast water as either living or dead,” Andersen explains. “The power of the 35kw UV lamps in the OBS ensures it has the power to instantly kill invasive organisms and that’s exactly what USCG wants to see.

“The system has now satisfied all marine water tests and is in its final testing stage, with full USCG approval expected later this year. For shipowners with large global fleets this gives them the flexibility to sail in and out of US waters, discharging ballast, as desired. For those with fleets based exclusively in North America this is a ticket to trade, full stop.

“USCG approval is becoming a benchmark standard for forward-thinking customers planning for guaranteed future regulatory compliance. This is proving to be a key business driver for Optimarin.”

Optimarin’s customers include names of the order of Saga Shipholding, MOL, Grieg Shipping Group, Gulf Offshore, Farstad Shipping, NYK, Nor Line, and Evergreen Marine Corp, amongst others. Its OBS system is easy to install, simple to maintain – with no moving parts – and does not use, or discharge, any chemicals.

“We believe we have an industry leading proposition,” Andersen concludes, “and it’s hugely satisfying to see the market respond to that at this key time for the BWT sector.”

New premises MacArtney Singapore, Asia Pacific Operations

New premises MacArtney Singapore, Asia Pacific Operations Xodus Group’s

Xodus Group’s Image credit: DOF Subsea

Image credit: DOF Subsea Fast Supply Vessels (FSV) are tasked with delivering cargo and crew to oil and gas platforms, and other offshore operations with speeds unheard of in a crew boat 20 years ago.

Fast Supply Vessels (FSV) are tasked with delivering cargo and crew to oil and gas platforms, and other offshore operations with speeds unheard of in a crew boat 20 years ago.  Damen Shipyards Group

Damen Shipyards Group Wood Group

Wood Group Subsea 7 S.A.

Subsea 7 S.A. Bristow Group

Bristow Group Roger Esson, chief executive, Decom North Sea

Roger Esson, chief executive, Decom North Sea The Edda Freya 304OCV offshore construction vessel with a length of 149.8m and beam of 27m is due to join the DeepOcean fleet early in 2016.With 2 off 220HP Constructor WROV’s moon pool handling, L&R 7m Hs and accommodation for 140 people. Credit: DeepOcean

The Edda Freya 304OCV offshore construction vessel with a length of 149.8m and beam of 27m is due to join the DeepOcean fleet early in 2016.With 2 off 220HP Constructor WROV’s moon pool handling, L&R 7m Hs and accommodation for 140 people. Credit: DeepOcean Credit: Crowley Maritime Corp.

Credit: Crowley Maritime Corp. As offshore topsides become heavier and more oil reserves are identified in harder to reach locations, innovative solutions are key to effective oil & gas extraction. As a result, floatover installations are experiencing an upturn, rather than traditional heavy crane lifting. JP Chia, Engineering Manager and floatover specialist for Trelleborg’s engineered products operation, will be on stand at OTC Houston to discuss this trend, share market insights and answer any questions.

As offshore topsides become heavier and more oil reserves are identified in harder to reach locations, innovative solutions are key to effective oil & gas extraction. As a result, floatover installations are experiencing an upturn, rather than traditional heavy crane lifting. JP Chia, Engineering Manager and floatover specialist for Trelleborg’s engineered products operation, will be on stand at OTC Houston to discuss this trend, share market insights and answer any questions. Photo credit: © Eni Norge

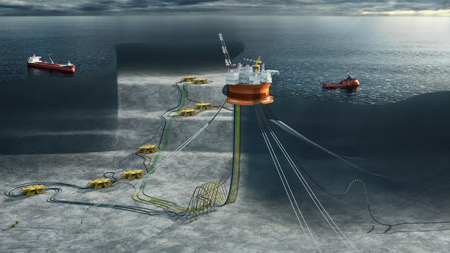

Photo credit: © Eni Norge Eni Goliat illustration overview. Credit: © Eni Norge.

Eni Goliat illustration overview. Credit: © Eni Norge. Dive Support Vessel, Neptunus. Image credit: N-Sea

Dive Support Vessel, Neptunus. Image credit: N-Sea

Ballast water treatment (BWT) specialist

Ballast water treatment (BWT) specialist