Ballast water treatment (BWT) specialist Optimarin has cemented its place at the vanguard of the market, with the news that it has now sold over 400 of its environmentally friendly UV-based systems. The landmark has been surpassed on the back of a succession of major contracts, fuelled by the firm’s unique retrofit experience, proven technology and upcoming USCG certification.

Ballast water treatment (BWT) specialist Optimarin has cemented its place at the vanguard of the market, with the news that it has now sold over 400 of its environmentally friendly UV-based systems. The landmark has been surpassed on the back of a succession of major contracts, fuelled by the firm’s unique retrofit experience, proven technology and upcoming USCG certification.

2016 has been a boom year for a company that installed the first ever commercial BWT system back in 2000. Optimarin Ballast System (OBS) orders have been confirmed with Atlantis Tankers (10 units) and Sinopacific Shipbuilding Group (nine), while the firm also made its first foray into fishing, with a contract for the Fisherman’s Finest vessel America’s Finest. The latest win, with Carisbrooke from the UK, was the largest - a fleet agreement with the potential to encompass retrofits on 46 bulk and multipurpose vessels.

“We’ve been working with BWT technology since our formation in 1994,” comments Optimarin CEO Tore Andersen, “so we feel this surge in business reflects an appreciation of our established expertise, technology, and ability to satisfy all individual customer, and vessel, requirements.

“Now that the ratification of the IMO’s Ballast Water Management convention is finally imminent, we’re seeing more and more shipowners engaging us for fleet wide retrofit assignments. This is because they know they can trust us, our market proven system, and unparalleled retrofit experience.”

Together with its global engineering partners, Goltens and Zeppelin, Optimarin has now fitted over 70 units on existing vessels, alongside over 200 on newbuilds. Its flexible, modular system is perfect for making the most of limited vessel space, while its totally compliant technology ensures peace of mind.

This latter point has proven to be another of Optimarin’s strengths. The firm has invested millions of dollars in testing and certification, with certificates from DNV GL, Lloyd’s, Bureau Veritas, MLIT Japan, and American Bureau of Shipping, alongside full IMO approval. However, it’s the latest testing with USCG that appears to be elevating the business to a new commercial plane.

“USCG has the most stringent approval demands, thanks to its FDA/CMFDA test, which judges the life forms transported in ballast water as either living or dead,” Andersen explains. “The power of the 35kw UV lamps in the OBS ensures it has the power to instantly kill invasive organisms and that’s exactly what USCG wants to see.

“The system has now satisfied all marine water tests and is in its final testing stage, with full USCG approval expected later this year. For shipowners with large global fleets this gives them the flexibility to sail in and out of US waters, discharging ballast, as desired. For those with fleets based exclusively in North America this is a ticket to trade, full stop.

“USCG approval is becoming a benchmark standard for forward-thinking customers planning for guaranteed future regulatory compliance. This is proving to be a key business driver for Optimarin.”

Optimarin’s customers include names of the order of Saga Shipholding, MOL, Grieg Shipping Group, Gulf Offshore, Farstad Shipping, NYK, Nor Line, and Evergreen Marine Corp, amongst others. Its OBS system is easy to install, simple to maintain – with no moving parts – and does not use, or discharge, any chemicals.

“We believe we have an industry leading proposition,” Andersen concludes, “and it’s hugely satisfying to see the market respond to that at this key time for the BWT sector.”

Damen’s FCS 2610 at sea. Image credit: Damen

Damen’s FCS 2610 at sea. Image credit: Damen Swimming down to subsea templates. Image credit: Kongsberg Maritime

Swimming down to subsea templates. Image credit: Kongsberg Maritime BOURBON

BOURBON Leading United Arab Emirates shipyard

Leading United Arab Emirates shipyard  These range from three recently delivered work crane boats for Kuwait Oil Company - optimized for duties such as heavy lifting, oil-pollution control, SPM hose handling, and supply to remote areas – to two modified 42 meter long crew boats (FNSA-3 and FNSA-4) for Fujairah National Shipping Agency. The latter vessels are capable of speeds in excess of 30 knots and customized to execute operations such as security duties, fast transportation of offshore personal and cargo, and the rapid supply of fuel and freshwater.

These range from three recently delivered work crane boats for Kuwait Oil Company - optimized for duties such as heavy lifting, oil-pollution control, SPM hose handling, and supply to remote areas – to two modified 42 meter long crew boats (FNSA-3 and FNSA-4) for Fujairah National Shipping Agency. The latter vessels are capable of speeds in excess of 30 knots and customized to execute operations such as security duties, fast transportation of offshore personal and cargo, and the rapid supply of fuel and freshwater. Credit: Crowley Maritime Corp.

Credit: Crowley Maritime Corp. Photo credit: Hydrex

Photo credit: Hydrex LFC 3000 artist impression

LFC 3000 artist impression Capable of intervening in the most complex environments, she boasts a bollard pull of 307 t

Capable of intervening in the most complex environments, she boasts a bollard pull of 307 t Fast Supply Vessels (FSV) are tasked with delivering cargo and crew to oil and gas platforms, and other offshore operations with speeds unheard of in a crew boat 20 years ago.

Fast Supply Vessels (FSV) are tasked with delivering cargo and crew to oil and gas platforms, and other offshore operations with speeds unheard of in a crew boat 20 years ago.  • One Year after Receiving Nautical Institutes Class A Certification, GE’s Houston Training Center for Mariners Receives Accreditation for Sea Time Reduction (STR) Course

• One Year after Receiving Nautical Institutes Class A Certification, GE’s Houston Training Center for Mariners Receives Accreditation for Sea Time Reduction (STR) Course Lance1. Photo credit: Wilhelmsen Ship Service

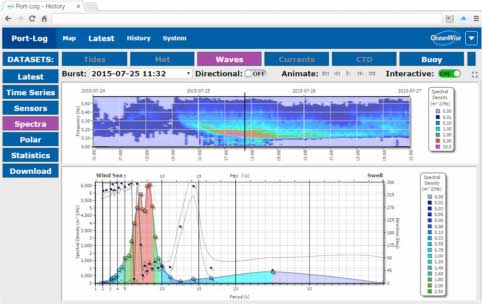

Lance1. Photo credit: Wilhelmsen Ship Service Output from Port-Log’s new waves processing capability.

Output from Port-Log’s new waves processing capability. Ballast water treatment (BWT) specialist

Ballast water treatment (BWT) specialist

Crowley Maritime Corporation

Crowley Maritime Corporation Life today demands a 24/7 connection, but reception on the water is notoriously uneven. Dropped calls and marginal service are a thing of the past for users of

Life today demands a 24/7 connection, but reception on the water is notoriously uneven. Dropped calls and marginal service are a thing of the past for users of