With an emphasis on efficiency improvements, Seadrill has chosen to extend its leasing of the SafeEx tablet-based software module for Ex inspections and registration, for use on seven units. At the same time, three new ones have also been added.

With an emphasis on efficiency improvements, Seadrill has chosen to extend its leasing of the SafeEx tablet-based software module for Ex inspections and registration, for use on seven units. At the same time, three new ones have also been added.

To further optimise their already quite modern fleet, Seadrill initiated a working relationship in March 2013 with SafeEx, a Danish company, whose products include software for Ex inspections that streamline procedures, improve documentation and increase safety.

Since then, Seadrill has leased the SafeEx Software for a total of 14 drilling rigs, including the seven for which the licenses were expiring and which have been renewed now for either one or three years. In addition, three new agreements were signed.

Ex inspections using the SafeEx Software are performed for Seadrill by third-party inspection firms, such as K2 Velosi for example. Previously, these inspections were conducted using pen and paper, but with the software solution from SafeEx they are now performed using a tablet containing General Arrangement (G.A.) Drawings and checklists for the unit concerned.

G.A. Drawings are interactive maps of the area concerned on the unit, where pointers show the equipment's exact position. Inspections of each individual piece of equipment are initiated by using the tablet to scan an RFID tag affixed to the equipment. This loads the related checklists, and data is registered directly. At the same time, it is possible to reposition equipment or register new equipment in the map.

"The G.A. Drawings provide extremely useful functionality. They are more efficient, simple to use and save time in comparison to the paper system previously used", says Oliver Donahue, Lead Inspector & Electrical Supervisor for K2 Velosi.

Inspectors can also take pictures with the tablet, for example of defects or non-conformities, and register them. In addition, the SafeEx Software features the significant benefit that all information is made available to onshore management instantaneously once the inspection has been performed.

According to K2 Velosi, this has both optimised the work procedures as well as improved documentation and safety, with further optimisation being expected for maintenance in future due to the system now having been implemented and become a natural part of the procedures.

"The SafeEx Software is a big improvement from the old system", emphasises Oliver Donahue.

The SafeEx Software is DNV approved and in addition to Seadrill is also used by companies such as Statoil, Petronas, TRESE/PEMEX, DONG Energy, Noble Drilling and BW Offshore.

Global integrated drilling waste management and environmental services firm, TWMA, has been shortlisted in the Export Achievement category at this year’s Offshore Achievement Awards.

Global integrated drilling waste management and environmental services firm, TWMA, has been shortlisted in the Export Achievement category at this year’s Offshore Achievement Awards. Aquatic's offshore team using harnesses and ladders to assemble modular reel drive system

Aquatic's offshore team using harnesses and ladders to assemble modular reel drive system With this new global framework agreement in place, Norwegian oil services company

With this new global framework agreement in place, Norwegian oil services company  Inge Alme, Sales Director at Lloyd’s Register said: “Aker Solutions’ efforts in efficiency stewardship are testament to their commercial and environmental commitment. They are demonstrating yet again that their efficiency programs are designed and implemented with high accuracy, completeness and transparency.”

Inge Alme, Sales Director at Lloyd’s Register said: “Aker Solutions’ efforts in efficiency stewardship are testament to their commercial and environmental commitment. They are demonstrating yet again that their efficiency programs are designed and implemented with high accuracy, completeness and transparency.” The companies will through a joint work group identify opportunities where they can create value for customers by combining

The companies will through a joint work group identify opportunities where they can create value for customers by combining  "We will team up with Saipem on targeted projects, providing integrated solutions that will enable our clients to make the most of their upstream investments, reduce development time and lower operating costs," said Luis Araujo, chief executive officer at Aker Solutions.

"We will team up with Saipem on targeted projects, providing integrated solutions that will enable our clients to make the most of their upstream investments, reduce development time and lower operating costs," said Luis Araujo, chief executive officer at Aker Solutions. Conductor Installation Services Ltd (CIS)

Conductor Installation Services Ltd (CIS) Crowley Maritime Corporation

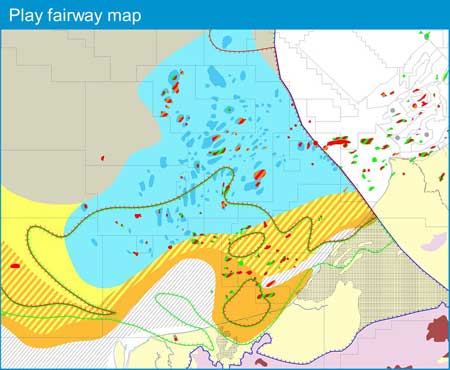

Crowley Maritime Corporation Example play fairway map showing distribution of fields, reservoir, seal and source kitchens linked to the play. Tellus provides rapid evaluation of proven and potential play elements, concepts and risks for over 2400 plays in 430 basins worldwide.

Example play fairway map showing distribution of fields, reservoir, seal and source kitchens linked to the play. Tellus provides rapid evaluation of proven and potential play elements, concepts and risks for over 2400 plays in 430 basins worldwide.

Wood Group has been awarded a new contract by PetroRio to deliver services to the Polvo A platform, in the southern Campos basin, approximately 100 kilometers off the coast of Rio de Janeiro. Integrated operations and maintenance services will be provided by Wood Group PSN under the two year contract, which is effective immediately.

Wood Group has been awarded a new contract by PetroRio to deliver services to the Polvo A platform, in the southern Campos basin, approximately 100 kilometers off the coast of Rio de Janeiro. Integrated operations and maintenance services will be provided by Wood Group PSN under the two year contract, which is effective immediately. Rob Spillard (photo) brings over twenty-five years’ experience in the offshore survey industry and will take overall responsibility for the technical direction of the Wirral-based company. Having previously performed key roles at Fugro EMU, the Maritime and Coastguard Agency and the United Kingdom Hydrographic Office, Rob will play an intrinsic part in the continuing growth of the company.

Rob Spillard (photo) brings over twenty-five years’ experience in the offshore survey industry and will take overall responsibility for the technical direction of the Wirral-based company. Having previously performed key roles at Fugro EMU, the Maritime and Coastguard Agency and the United Kingdom Hydrographic Office, Rob will play an intrinsic part in the continuing growth of the company. M-I SWACO has developed a new technological solution and has now been awarded a contract with

M-I SWACO has developed a new technological solution and has now been awarded a contract with  Wood Group

Wood Group With an emphasis on efficiency improvements,

With an emphasis on efficiency improvements,

Subsea 7 S.A.

Subsea 7 S.A. Amec Foster Wheeler announces today that it has been awarded three contracts by BP to provide services to the Glen Lyon Floating Production, Storage and Offloading (FPSO) vessel as part of the Quad 204 Project, located 175 km west of the Shetland Isles, UK. The three reimbursable contracts are worth £31.5 million and will create 100 onshore and 50 offshore jobs.

Amec Foster Wheeler announces today that it has been awarded three contracts by BP to provide services to the Glen Lyon Floating Production, Storage and Offloading (FPSO) vessel as part of the Quad 204 Project, located 175 km west of the Shetland Isles, UK. The three reimbursable contracts are worth £31.5 million and will create 100 onshore and 50 offshore jobs.