Classification society DNV GL, Kongsberg Maritime and Subsea7 have successfully concluded the pilot testing of Kongsberg Maritime’s (KM) DP Digital Survey (KMDS) application on board the Subsea7 vessel Seven Kestrel. The pilot tested the use of a remote digital verification tool for testing dynamic positioning (DP) systems as part of DNV GL’s D-Class project.

In March 2019, DNV GL rolled out the first fleet-wide remote survey scheme for some inspections in the classification industry. This means that for some surveys, a DNV GL surveyor is not required to travel to the vessel, but instead, input provided by the customer and crew is used to demonstrate compliance. This saves travel costs, waiting time, and reduces vessel downtime. The scheme has been warmly greeted by both customers and flag states.

Testing the dynamic positioning (DP) systems on vessels in operation has also traditionally required a surveyor visit, often alongside DP failure mode and effects analyses (FMEA) consultants and equipment vendor experts, to witness verification trials. Coordinating and conducting these tests with multiple partners can result in a vessel being taken out of operation for several days.

“The digital survey is an opportunity to deliver on our DP verification focus areas by capturing data from what are currently seen as routine events, enabling us to use these recordings as verification of our asset performance. This technology also gives us a higher data quality than we currently receive through manual trials and gives us a permanent tamper proof recording of the event. The test methodology used within the application also empowers the crew to take ownership of the system and give them greater confidence in the DP system setup onboard their vessel. This will provide us with a more robust survey and we see this as a lead into greater safety through familiarization within our fleet,” said Bryce Heslop, Marine Technical Manager at Subsea 7.

To try and reduce the burden of verifying DP systems on its customers, by enhancing efficiency while maintaining effectiveness and safety standards, DNV GL launched the Data Smart Classification or D-Class Project in 2017. It is designed to evaluate and work toward the acceptance of new methods and technology for the verification of DP systems.

“We have been involved in the D-Class project from the beginning. It offered a way for us to see how we can be more innovative in our approach to DP verification, and to improve the efficiency of our DP verification programs without compromising the safety of our asset while maintaining the integrity of the traditional survey. At Subsea 7 we pride ourselves in our open and collaborative approach with our suppliers and classification societies, so we saw this as an opportunity to strengthen ties, improve performance, and lead by example in the DP industry,” said Graeme Lorenson, DP/Electrical and Controls Team Lead at Subsea 7.

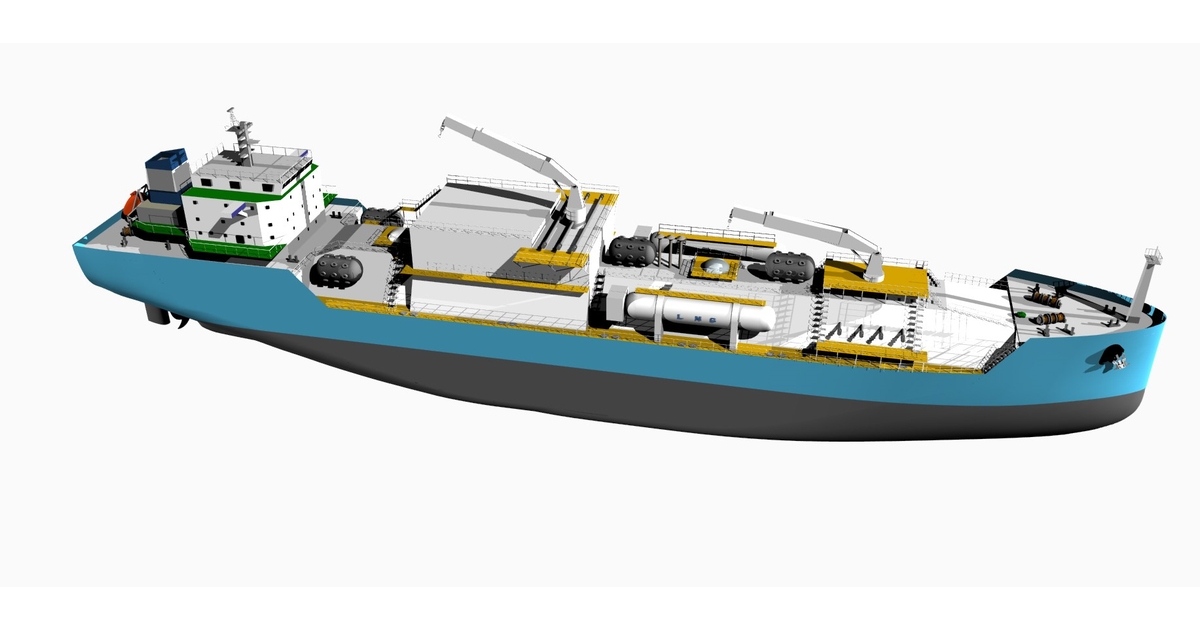

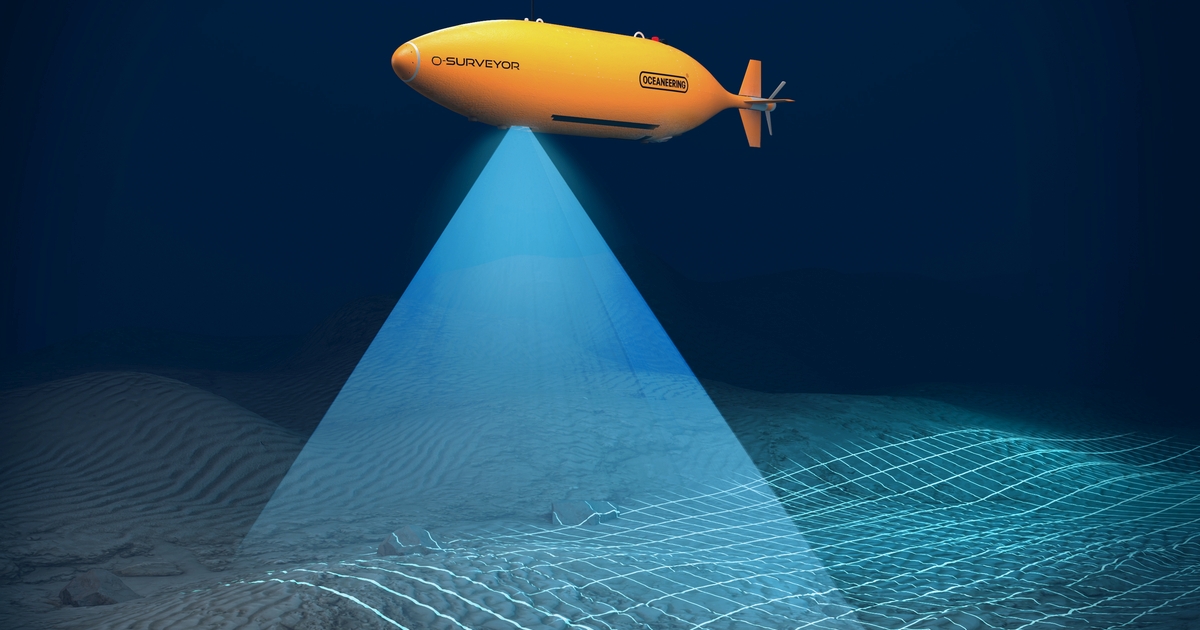

As part of the D-Class project, DNV GL initiated a pilot to examine the possibility of using Kongsberg Maritime’s DP Digital Survey tool in annual verification trials. The pilot used the tool on board Subsea7’s diving support vessel Seven Kestrel and covered both class survey requirements and standard international industry tests. The tool takes data directly from a vessel’s control systems and transmits this to a secure cloud, where it is available for assessment by expert verifiers, class, and vendors.

“The KM-DPDS application offers our customers a tool that will potentially reduce their OPEX for each DP vessel and increase the vessel’s uptime, as the individual DP trial tests can be executed during non-productive time. The competence of DP key personnel is enhanced as well,” said Eivind Alling, Vice-President of Digital Performance at Kongsberg Maritime. “The collaboration with DNV GL and Subsea7 has been of paramount importance to develop criteria for the digitalization of the Annual DP trial program, based on IMO MSC/Circ.1580, the DNV GL DP class notation and IMCA M 190 guidance document. The successful completion of the pilot paves the way for an application of a DNV GL Approval in Principal for the KM-DPDS solution.”

“With this pilot, we have proof-of-concept for using the KMDS application for verification of DP systems. This technology has the potential to provide secure and tamper-proof collection of system-generated data, which can be used as evidence for performing objective remote office assessment by class. The data collected will also form a significantly improved body of evidence for documenting test results, which can help to increase confidence in DP systems,” said Aleks Karlsen, DNV GL Senior Principal Specialist DP systems.

“This is another step forward in the wider application of remote verification technologies. The experience we have gained from working on this pilot has provided valuable experience and input to our D-Class rules and standard development. We plan to launch the results of this development by the end of this year,” added Jan van Tiggelen, DNV GL Project Manager for D-Class.