Logan Industries (Logan), a hydraulic repair, manufacturing and rental company, has opened a new Pressure Vessel Heat Exchanger (PVHEX) facility at its Hempstead, Texas, site. The new state-of-the-art facility enables Logan to manufacture, test, certify and stamp high-end alloy vessels.

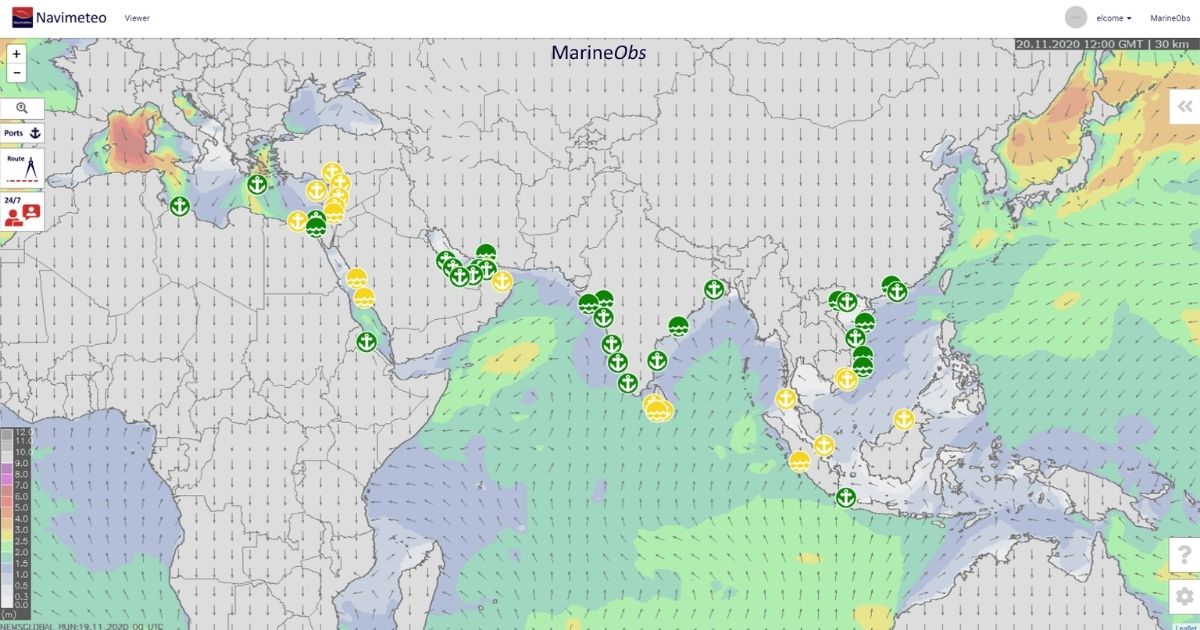

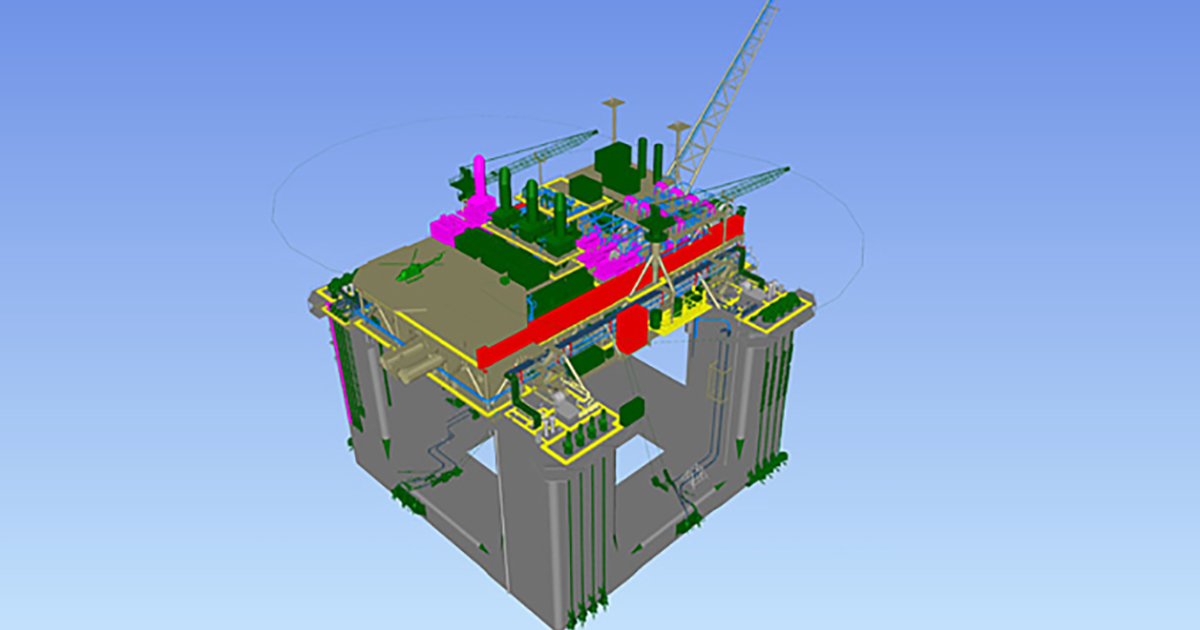

The PVHEX facility is custom designed and engineered to efficiently produce exotic metal pressure vessels, heat exchangers and scrubbers for the petrochemical, marine, ocean transport, chemical and nuclear industries. The building is serviced with several pairs of 40-ton bridge cranes, with specially engineered crane supports enabling lifts of up to 80 tons. A reinforced foundation supports water testing of the largest vessels and a positive pressure workspace with its own closed-circuit ventilation system controls air-borne contaminants in the manufacture of exotic metal fabrications.

Logan will initially service the customers of Dutch sister company, Verolme, a long-time manufacturer of PVHEX, eliminating transit times from Europe to its U.S. customers in the process. The new facility also enables additional high alloy ASME type products to be produced in the U.S. An additional sister company, Schelde Exotech, also based in The Netherlands, will work hand-in-hand with Logan and Verolme. Together, the three companies will each be able to manufacture high-end, exotic alloy pressure vessels, heat exchangers, and scrubbers according to Dean Carey, technical director, Logan Industries, said, “This PVHEX facility is world class and represents a major milestone in the co-operation between Logan and our sister companies. The facility’s physical proximity to our current site in Hempstead means that when our customers come to see us, the location is already familiar to them. We can also shift our staff and resources as the workload dictates from one facility to the other without any logistical effort or delay. Once we develop our own footprint, the market for these PVHEX products will be worldwide.”

Logan has named Jan M. Contreras as its new manager of sales - pressure vessels and heat exchangers (PVHEX). Based in Houston, Contreras will be responsible for PVHEX sales and business development, showcasing Logan’s new state-of-the-art PVHEX facility in Hempstead, Texas, and growing business for Dutch sister companies Verolme and Schelde Exotech, across North America.

Contreras has more than 35 years of experience in the PVHEX and fired heater sector, having acquired deep industry knowledge in design, manufacturing, quality and logistics. With specialties in international business development and sales, welding and contract management, Contreras is also experienced in delivering lectures and presentations on PVHEX, CAD and physics topics within a diverse array of professional and educational institutions.

Carey said, “During our initial meetings with Jan, he demonstrated an exceptional understanding of the pressure vessel and heat exchanger business, and the value he offered to Logan Industries as such a strong engineering professional was clear. In addition to his business development and sales expertise, Jan is well equipped to provide support on the technical side of the product, making him an excellent technical salesperson to benefit our customers.”

The PVHEX facility encompasses more than 50,000 sq. ft of covered workspace and will eventually employ approximately 15-20 new staff.

For more information, visit here.