Equinor and its license partners have decided to invest NOK 3 billion in the North Sea Statfjord Øst field to improve recovery by 23 million barrels of oil equivalent.

Written notification of material changes to the Plan for Development and Operation Statfjord Øst was submitted to the Ministry of Petroleum and Energy 16.12.2020.

“The decision to improve recovery on Statfjord Øst will add considerable value to society and owners and will create positive effects for suppliers. Our ambition is to maintain safe and profitable production and secure valuable activity from the Norwegian continental shelf (NCS) for several decades,” says Kjetil Hove, Equinor’s senior vice president for Field Life eXtension (FLX).

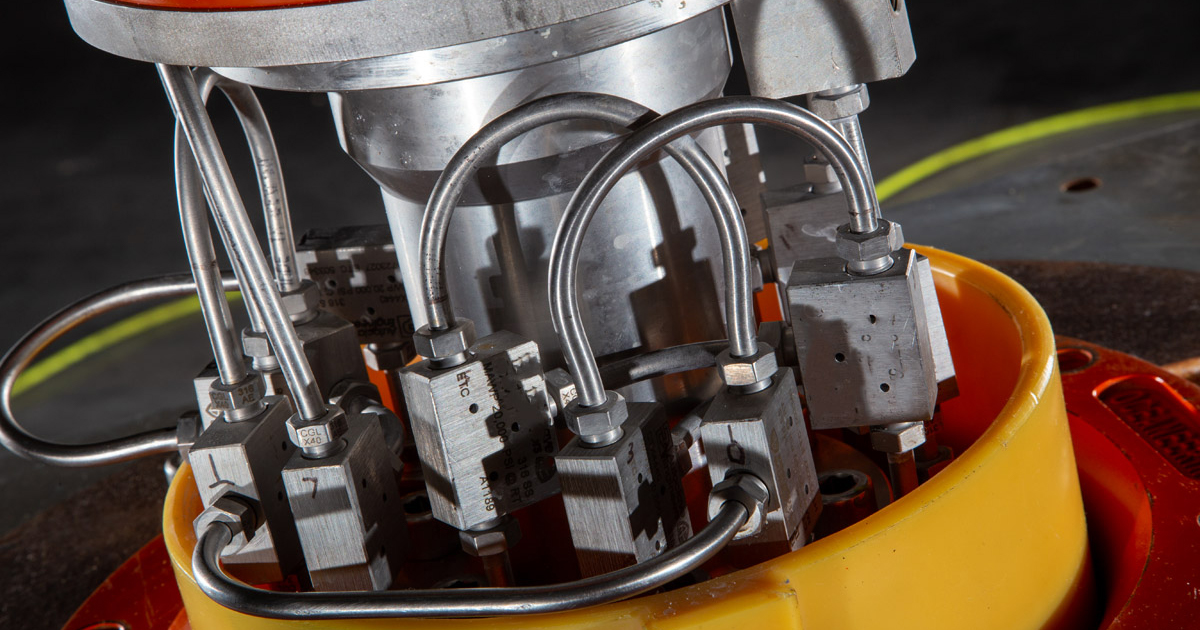

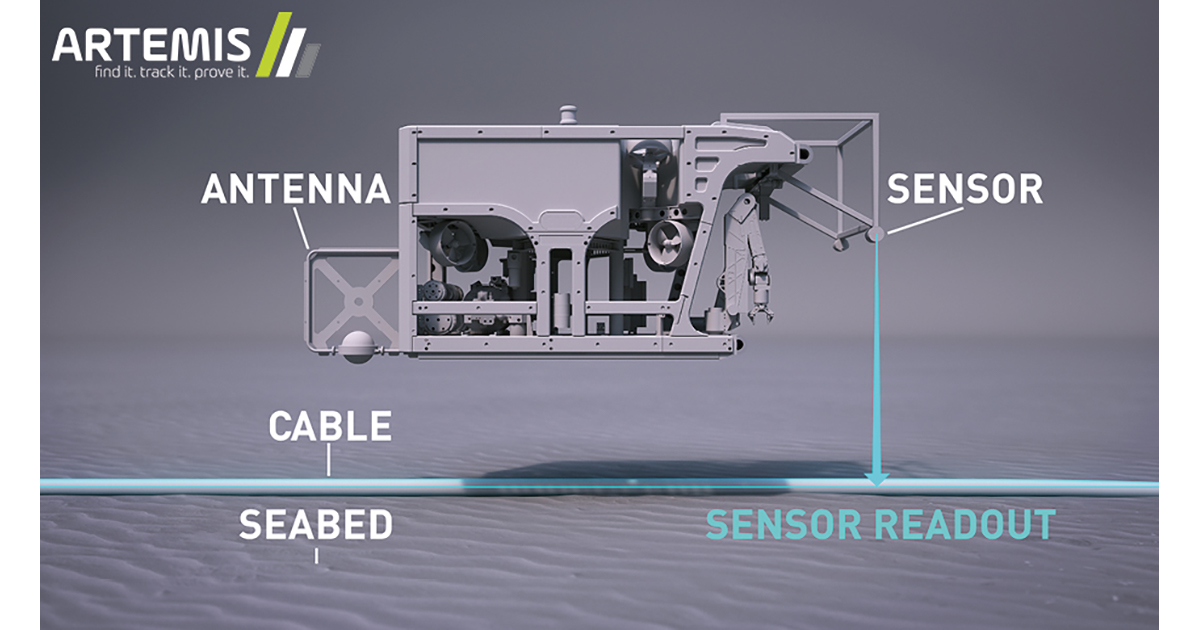

Statfjord Øst is tied back to the Statfjord C platform by pipelines. A total of four new wells will be drilled from existing subsea templates. The project also includes modifications on Statfjord C and a new pipeline for gas lift.

Kjetil Hove, Equinor’s senior vice president for Field Life eXtension. (Photo: Ole Jørgen Bratland)

“We will be a leading late life operator on the NCS. In order to achieve this, we must work in new ways to reduce costs, thereby offering new opportunities for investments in late life fields ensuring profitable reservoir management. The Statfjord Øst decision is a good example of this,” says Hove.

This decision enables an improvement of the recovery factor on Statfjord Øst and gives an important contribution to extending the life of the Statfjord C platform and the Statfjord Øst field towards 2040.

The original oil volume in place on Statfjord Øst was 415 million barrels of oil. The current recovery factor is 56 percent. As a result of this project, the expected recovery factor is increased to 62 percent.

Anders Opedal, president and CEO of Equinor, submitted the Written notification of material changes to the Plan for Development and Operation Statfjord Øst to Tina Bru, Minister of Petroleum and Energy. (Photo: Ole Jørgen Bratland)

Anders Opedal, president and CEO of Equinor, submitted the Written notification of material changes to the Plan for Development and Operation Statfjord Øst to Tina Bru, Minister of Petroleum and Energy. (Photo: Ole Jørgen Bratland)

Plans call for installation of a pipeline for gas lift, modifications on Statfjord C and drilling of new wells in 2022 - 2024. Production start is scheduled for 2024.

The Statfjord Øst development comprises subsea installations that include three templates. The field is located five kilometers north-east of Statfjord C. The field came on stream in 1994.

The licence partners in Statfjord Øst Unit: Equinor Energy AS (31.6875%), Petoro AS (30.0000%), Vår Energi AS (20.5500%), Spirit Energy Norway AS (11.5625%), Idemitsu Petroleum Norge AS (4.8000%), Wintershall Dea Norge AS (1.4000%).

After several extensions of the Statfjord field life, the current goal is to maintain safe and profitable operation until 2040. Statfjord is part of FLX, which was established to meet the strategic opportunities and challenges of late life fields in relation to Equinor’s competitiveness.

FLX aims to ensure that Equinor is the leading company in safe and efficient operations with low carbon emissions from late life fields on the NCS.

Anders Opedal, president and CEO of Equinor, submitted the Written notification of material changes to the Plan for Development and Operation Statfjord Øst to Tina Bru, Minister of Petroleum and Energy. (Photo: Ole Jørgen Bratland)

Anders Opedal, president and CEO of Equinor, submitted the Written notification of material changes to the Plan for Development and Operation Statfjord Øst to Tina Bru, Minister of Petroleum and Energy. (Photo: Ole Jørgen Bratland)