Subsea IMR provider, N-Sea, has been awarded a new contract with Galloper Offshore Wind Farm Ltd (GWFL).

The contract for pre-construction unexploded ordnance (UXO) clearance works commenced in April 2016 and includes UXO risk management, target investigations and clearance on the Galloper Wind Farm, off the coast of Suffolk.

Expected to run for between 3-6 months, the project sees the Siem N-Sea multi-support vessel utilize a WROV to investigate potential UXO targets within the array areas and export cable corridor. N-Sea’s dive support vessel, Neptunus, will also undertake similar tasks in shallow water areas.

Dive Support Vessel, Neptunus. Image credit: N-Sea

Dive Support Vessel, Neptunus. Image credit: N-Sea

To complete the clearance works, N-Sea has sub-contracted Ordtek Ltd (provider of unexploded ordnance risk management for land and marine developments), Modus Seabed Intervention (work class ROV and crew hire) and Ramora UK (Explosive Ordnance Disposal services).

Chief operating officer at N-Sea, Roddy James, said: “We are delighted to have the opportunity to contribute to the development of the Galloper project, which is a key part of the UK’s renewable energy portfolio.

“N-Sea has an impressive track record of unexploded ordnance campaigns in harsh conditions, which was key to our success in securing this contract. Our personnel and equipment resources are at the leading edge of UXO services, and our efficient, robust systems ensure we complete every project safely, on-time and within budget. This is a clear reflection of our ability to always provide safe, sound and swift solutions for our clients.”

N-Sea is known for its innovative work as an independent offshore subsea contractor, specializing in IMR services for the oil and gas, renewable and telecom/utility industries, as well as for civil contracting communities. N-Sea provides near shore, offshore and survey services to major operators and service companies alike.

Ordtek Ltd recently launched a Mine Map sharing information regarding UXO around the UK coastline. The map illustrates that the Galloper area, was heavily mined in the First and Second World Wars, and has been an active British military training area.

Ordtek director Lee Gooderham: “We are delighted to be working on this important renewable energy project off our local Suffolk shoreline. This is significant and complex project for us, with considerable ordnance has previously been found at the neighbouring Greater Gabbard site.”

Xodus Group’s

Xodus Group’s Subsea 7 S.A.

Subsea 7 S.A. Technip USA, Inc.

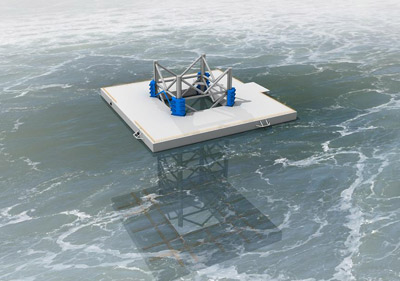

Technip USA, Inc. CALM OCEAN 101 will look like nothing else at sea: a broad, square deck surrounding a lone open-truss square jackup leg measuring 20 meters on each side. Image credit: Calm Ocean

CALM OCEAN 101 will look like nothing else at sea: a broad, square deck surrounding a lone open-truss square jackup leg measuring 20 meters on each side. Image credit: Calm Ocean The Edda Freya 304OCV offshore construction vessel with a length of 149.8m and beam of 27m is due to join the DeepOcean fleet early in 2016.With 2 off 220HP Constructor WROV’s moon pool handling, L&R 7m Hs and accommodation for 140 people. Credit: DeepOcean

The Edda Freya 304OCV offshore construction vessel with a length of 149.8m and beam of 27m is due to join the DeepOcean fleet early in 2016.With 2 off 220HP Constructor WROV’s moon pool handling, L&R 7m Hs and accommodation for 140 people. Credit: DeepOcean

Wild Well Control, Inc.

Wild Well Control, Inc. Photo credit: Intertek

Photo credit: Intertek Dive Support Vessel, Neptunus. Image credit: N-Sea

Dive Support Vessel, Neptunus. Image credit: N-Sea Bristow Group

Bristow Group Scott Meints

Scott Meints Adolfo Aguilera

Adolfo Aguilera Olympic Ares. Photo credit: Bibby Offshore

Olympic Ares. Photo credit: Bibby Offshore Image credit: DOF Subsea

Image credit: DOF Subsea Aker Solutions

Aker Solutions

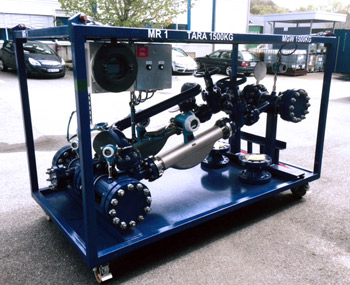

Rotech Subsea RS excavation tool, as fitted with a Tritech Gemini NBI. Image courtesy of Rotech Group Ltd

Rotech Subsea RS excavation tool, as fitted with a Tritech Gemini NBI. Image courtesy of Rotech Group Ltd