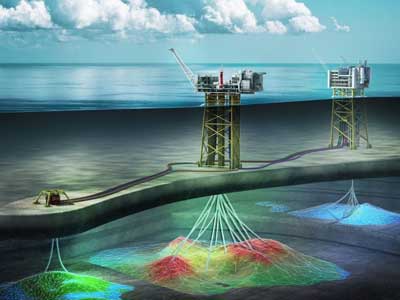

Ezra Holdings Limited (“Ezra” or the “Group”), a leading contractor and provider of integrated offshore solutions to the oil and gas industry, is pleased to announce that it has received the awards for several new deepwater projects from international oil majors. The awards are valued at approximately US$300 million in aggregate and will be executed in various offshore oil producing regions in the Gulf of Mexico, Southeast Asia and West Africa. Furthermore, the awards include the Group’s largest project win to-date in West Africa.

Ezra Holdings Limited (“Ezra” or the “Group”), a leading contractor and provider of integrated offshore solutions to the oil and gas industry, is pleased to announce that it has received the awards for several new deepwater projects from international oil majors. The awards are valued at approximately US$300 million in aggregate and will be executed in various offshore oil producing regions in the Gulf of Mexico, Southeast Asia and West Africa. Furthermore, the awards include the Group’s largest project win to-date in West Africa.

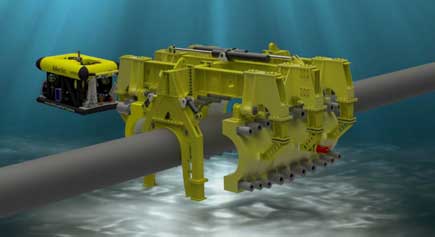

The scope of work for these new projects include project management, engineering, procurement, fabrication, construction as well as transport and installation of flexibles, umbilicals, flowlines, flowline-end terminals, flying leads and other equipment. Further to this, the Group will also undertake hook-up of pre-laid mooring systems.

Mr. Lionel Lee, Ezra’s Group CEO and Managing Director, said, “We are delighted to have been selected for these projects. Over the years, we have successfully developed a proven track record for completing the most technically demanding projects. Against the backdrop of such challenging and competitive industry conditions, these latest contract awards stand as exceptionally strong testaments to the market’s confidence in our team and our offerings. We are grateful for these opportunities to further galvanize our reputation and look forward to safely delivering on these projects on time and on target.”

Project management and engineering work for the projects have already started.

EMAS, a leading global contracting group, providing offshore/subsea construction, marine, production and well intervention services – is Ezra’s operating brand. With offices across six continents, it delivers best-value solutions to the oil and gas (O&G) industry by combining its global footprint and proven engineering skills with a diverse offering of premium assets and services designed to fully meet clients’ needs.

Operating in unison, Ezra’s core divisions are able to execute a full spectrum of seabed-to-surface engineering, construction, marine and production services anywhere in the world.

EMAS CHIYODA Subsea is a global EPCIC (Engineering, Procurement and Construction) service provider of comprehensive subsea-to-surface solutions throughout the lifecycle of oil and gas projects. On 31 March 2016, Chiyoda Corporation completed its investment in the Group’s subsea services business, EMAS AMC, to form EMAS CHIYODA Subsea - a 50:50 Joint Venture. EMAS Energy provides well intervention and drilling services both onshore and offshore, offering fully integrated solutions that combine its marine assets with state-of- the-art intervention equipment and services.

EMAS Marine, under subsidiary company EMAS Offshore Limited, manages and operates a young, versatile fleet of advanced offshore support vessels, offering an extensive range of maritime services that cater to the client’s needs throughout a field’s life cycle.

EMAS Production, also under subsidiary company EMAS Offshore Limited, owns and operates FPSO (floating production, storage and offloading) facilities, offering services that support the post-exploration needs of offshore fields, such as FPSO conversion management.

TRIYARDS is fast becoming an acknowledged leader in developing advanced and customized solutions for world-class vessels. By focusing on sophisticated platforms and equipment that can tackle even the most complex offshore projects, it has already established itself as a front runner in the fabrication of liftboats (self-elevating, mobile offshore units). TRIYARDS provides its integrated engineering, ship construction and fabrication services out of yard facilities located in Singapore, Vietnam and the US.

From left to right: Mike Churchill, CEO & Commercial Director, Churchill Drilling Tools, Anke Heggie, Company Growth Support Director, Scottish Enterprise, Andy Churchill, Chairman & Technical Director, Churchill Drilling Tools

From left to right: Mike Churchill, CEO & Commercial Director, Churchill Drilling Tools, Anke Heggie, Company Growth Support Director, Scottish Enterprise, Andy Churchill, Chairman & Technical Director, Churchill Drilling Tools Photo credit: Subsea Innovation

Photo credit: Subsea Innovation

Photo courtesy: BSEE

Photo courtesy: BSEE McDermott will manufacture structures for the Abkatun-A2 project at the Altamira, Mexico fabrication facility, shown here during the successful load out of the PB Litoral A project. Photo credit: McDermott

McDermott will manufacture structures for the Abkatun-A2 project at the Altamira, Mexico fabrication facility, shown here during the successful load out of the PB Litoral A project. Photo credit: McDermott

LQT Industries, LLC

LQT Industries, LLC Zohr gas field offshore Egypt

Zohr gas field offshore Egypt Photo courtesy: Maersk Oil

Photo courtesy: Maersk Oil Ivar Aasen, Det Norske

Ivar Aasen, Det Norske

Photo courtesy: Fugro

Photo courtesy: Fugro Peregrino field. Photo courtesy: Statoil

Peregrino field. Photo courtesy: Statoil

Ezra Holdings Limited

Ezra Holdings Limited Phil Stockton, Director, Accord Energy Solutions. Photo courtesy: Accord Energy Solutions

Phil Stockton, Director, Accord Energy Solutions. Photo courtesy: Accord Energy Solutions